The Myth

Hempcrete can replace standard concrete.

The Background

Hempcrete is a material that has been around for a long time. The most common mix that we have seen and heard about is made by the combination of hemp hurd (woody inner core), lime and water. It looks like American Hemp, LLC confirms this.

According to hempcretewalls.com, the mix is purported to be a strong insulator, flame resistant, pest resistant, moisture balancing and biodegradable (when exposed to water). Further, it is said to be more sustainable than concrete and a carbon sink. Hempcrete can also be reused through milling and rehydration.

Standard concrete is a mix of sand, aggregate (gravel) and Portland Cement. Concrete works, through a process called hydration where water reacts with the Portland Cement to harden (Popular Mechanics). Concrete is the most common building material in use around the world (Chemistry Society). It is used predominantly in the following applications:

- Footings (part of the foundation)

- Stem walls (part of the foundation and sit on the footings)

- Foundation slabs

- Elevated slabs

- Sidewalk

- Curb

- Bridges

- Dams

- Septic tanks

Hemp has been deemed by many as a miracle crop with ?25,000? uses and that it ?can save the world.? One particular use of hemp, often touted, is the potential to replace, standard concrete. The crop has been reported as better for the environment, easier to grow and ?has been suppressed for decades by corporate interests.?

?Now is the time for hemp to regain its rightful place,?? is a common statement we hear from many people.

For this myth we are going to look at what it would take to replace standard concrete with hempcrete in the scope of pricing and performance.

As with all hemp products or hemp derivatives, many look at them as a major disruptor of standard industries and a pathway to save the world. So, we are going to jump in, review the data, do a little math and see just how true this hemp myth really is.

Concrete Bridge

Concrete Bridge

The Data

For this myth, we will focus on a few primary data points including:

- The cost differentials of hempcrete vs standard concrete

- Performance limitations of hempcrete

The cost of a yard

Concrete is a very inexpensive material, relative to other materials. Here are some data points for concrete:

- Concrete is sold by the yard

- Our examined batch (according to data on our batch ticket) weighs 3,690 pounds per yard

- A yard is equal to 27 cubic feet

- Our examined batch (according to data on our batch ticket) weighs 137 pounds per cubic foot

- The average cost of a yard of concrete is $108 or 10,800 cents (NRMCA)

With that data we can see that the average selling price per concrete is $0.0293 per pound. We?ll model a 40% gross profit margin which equates to a cost of goods sold (COGS) $0.018 per pound. Now this is for the entire concrete mix. Hemp isn?t able to replace everything. Let?s take a look at a concrete batch ticket (this is the document that records the exact weights of all materials used to make the batch). We found this one online:

- Water ? 216 lb

- Cement ? 4,065 lb

- Aggregate (??) ? 10,460 lb

- Aggregate (???) ? 2,810 lb

- Aggregate (sand) ? 11,970 lb

- Total weight ? 29,521 lb

- Total yards ? 8

- Weight per yard ? 3,690 lb

So we can see a lot of weight goes into making concrete. The point here is to break down the concrete mix and see where we can add hemp and what that cost structure would have to look like. We obviously can?t replace the water with hemp nor the cement. We?ll go with the traditional hemp mix which again, is hemp, water and lime (cementitious material).

So let?s follow that rule and just replace all of that aggregate with hemp. This is our new mix design:

- Water ? 216 lb

- Cement ? 4,065 lb

- Hemp ? 25,240 lb

- Total weight ? 29,251 lb

- Total yards ? 8

- Weight per yard ? 3,690 lb

Great, we have a mix design.

Now to be cost competitive and be able to ?replace concrete? we would have to maintain a similar price point of $108 per yard or $0.0293 per pound. That is the selling price, the purchase price to make that would be 40% less (assuming the manufacturer makes a 40% margin). With that the COGS is $0.018 per pound. To keep things simple, let?s assume that the costs are evenly distributed across all the mix components (this is not the real case as the cement is significantly more expensive than the aggregate or water).

The value of hemp would be $0.018 per pound. If irrigated land can produce 8 tons of hemp material and 50% of that material is hurd that we will use in our hempcrete, then each acre can produce 8,000 lb of hurd for our hempcrete. At that production rate and price point, the farmer can expect to gross $140 per acre. The cost of seed alone is going to be $105 (using HGI pricing and seeding at 30 lb per acre). With the cost of seed accounted for, the farmer can expect to gross no more than $35 per acre and that is before the seed is even put into the ground! The real problem is the material must be decorticated, separated and shipped in order to be incorporated into hempcrete. At the current rates for concrete, it is not economical for farmers to grow hemp for hempcrete.

On the supply side, the numbers aren?t looking too good either. What about the demand side, the cost difference of the aggregate or sand compared to hemp?

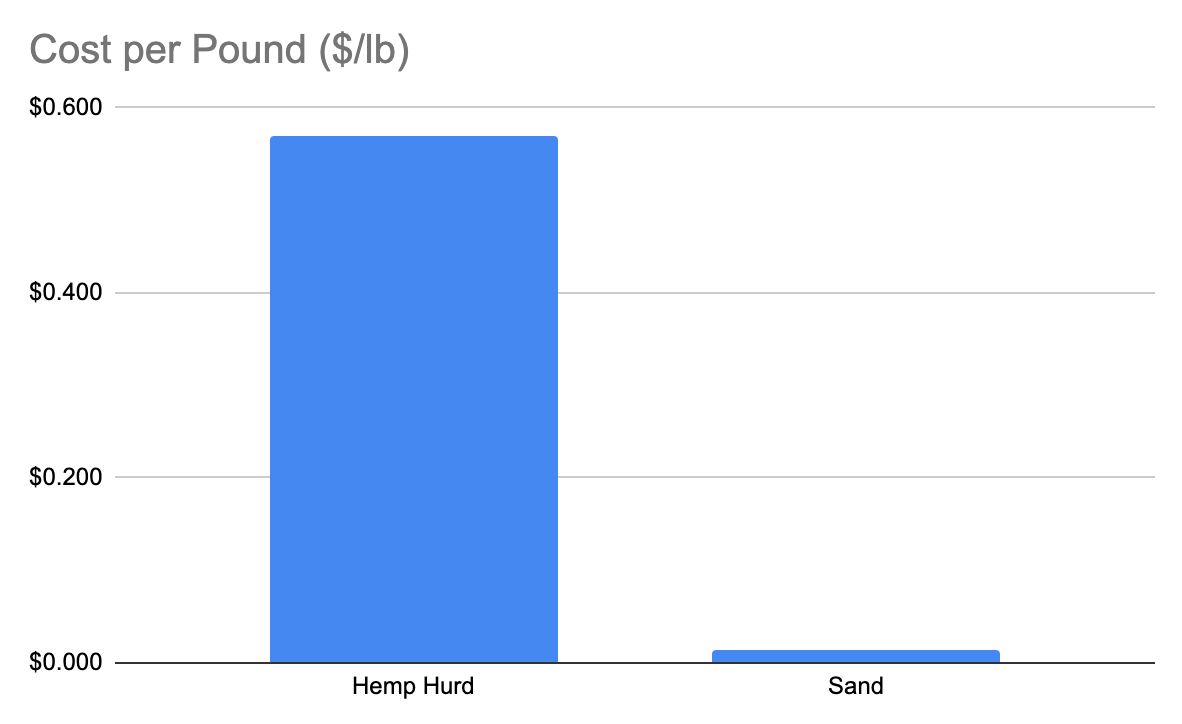

Based on our mix design above, we can see that sand is a major component of the concrete mix. We found sand pricing at $15 to $40 per yard according to homeadvisor.com. Let?s give hemp the best chance we can and use the higher, $40 per yard, price. The weight of that yard is 2,750 pounds according to DownEaster MFG. With this data the price per sand is $0.015 per pound. This pricing is lower than our original cost estimate, assuming an even distribution of cost. According to Hemptopia, FTL (full truck load) hemp hurd is $0.57 per pound. Here is a cost comparison chart:

Concrete Component Cost Comparison

Concrete Component Cost Comparison

We can see that significant price compression is needed to make hemp a viable replacement for sand. Since sand is classified as aggregate (based on our batch ticket) it is reasonable to assume that other aggregates will share a similar cost differential.

BUT

What if this is a waste product? What if the farmer actually grew for CBD or textile fiber or grain or something else? What effect would that have on our hempcrete?

Well, in that scenario, we can say that the cost of production is $0 since all the production costs can be applied to the other products. However, the decortication cost would have to be applied to the hurd unless the target product is fiber, which would be able to cover the decortication expense. We?ll assume that decortication costs are covered by fiber. Now things are starting to look good, right? We have 8,000 lb of hemp hurd per acre ready to be turned into hempcrete.

But here is the problem, that hemp hurd needs to get to the batch plant to be turned into concrete. The last shipping we had to deal with was $1,300 to transport 80,000 pounds of hemp (whole plan) about 144 miles. That is a transport cost per pound of $0.01625 per pound or about 92.7% of the value of the hemp.

We can now see that the cost structure of hempcrete will not allow it to replace concrete unless farmers are willing to net $0.00127 per pound of hemp (assuming all other costs are recorded elsewhere). At that rate, that makes hemp hurd worth $10.16 per acre to the farmer.

With all of that information, making a concrete replacement from hemp would not pencil out. The economics, whether you look at the supply side (farmer willingness to grow and profit) or the demand side (cost difference of the batch plant switching to hemp) simply doesn?t support this myth.

That being said, there will always be smaller, niche applications of this material. But the context of the myth is the ?Hempcrete can replace concrete?, so we are looking at the potential for that scenario to play out. Thus far, it is not looking good.

Hempcrete ? Performance

We can see the pricing of hempcrete is not competitive but let?s say we want hempcrete for all of the benefits and don?t care much about the cost. Here we are going to run into more problems.

Again, we are looking at hemp replacing concrete within the construction sector which requires hempcrete to maintain target specifications inherent in concrete.

Concrete is an incredible construction material. It is inexpensive, non toxic when cured, can last for thousands of years, fire resistant, pest resistant, maintains very good compressive strength and is easy to work with. It is also water tolerant as we can see in its use of septic tanks, water holding tanks, dams and many more.

Hemp in contrast is also non toxic when cured, fire resistant, pest resistant, mold resistant, can last a long time (unless it gets soaked with water which causes it to degrade) but maintains minimum compressive strength.

The primary performance indicator for concrete is compressive strength. During placement, concrete is tested in the field for a few different attributes including, slump, air content, weight and temperature. Concrete cylinders are cast in the field and then cured. The cured samples are tested for compressive strength on Day 7 and Day 28. To test compressive strength, a hydraulic piston is used to apply consistent pressure until the cylinder cracks or otherwise breaks.

Now most concrete must hit a compressive strength of 3,000 psi to 4,000 psi and most concrete (given they are not high in air content) can easily hit this. Hempcrete, on the other hand would not hit this specification.

According to hempcretewalls.com, hempcrete has a compressive strength of 0.5 MPa to 3.5 MPa or 72.5 psi to 507.6 psi. At best that is 16.9% the strength of standard concrete. To put that in perspective, according to the Wikipedia page regarding Ground Pressure, a stiletto heel can exert up to 471 psi. Imagine seeing someone walk down the sidewalk and their heels penetrating and poking holes in the sidewalk with each step.

The reasoning behind this is quite simple. Hempcrete is composed of very little dense material (Hemptopia says the bulk density is 0.152 g/cm3 or 9.5 lb/ft3) whereas concrete contains, sand and multiple sizes of aggregate (with a bulk batch density of 137 lb/ft3 based on our batch ticket). These ingredients each add considerable compressive strength due to their density.

No matter where you go, there will be a public work specification which will outline the compressive strength of concrete. This specification must be met or the concrete will be rejected and whatever was made with it removed.

Hempcrete can provide some tensile strength, if the fibers are utilized. This helps reduce surface cracking but does not increase the compressive strength. At this time, we are unaware of any specification for tensile strength. Further, there are many other types of fibers that can be added to concrete to increase the tensile strength including steel and nylon.

So with this we can see that in one, if not, the most critical areas (depending on who you ask, contractor vs inspector), hempcrete just doesn?t provide the same performance as standard concrete and will be unable to without the addition of more dense materials. Also, when exposed to excess water, hempcrete can biodegrade whereas standard concrete can hold up to large amounts of water (think dams that are over 100 years old) for a very long time with minimal degradation.

The Myth ? BUSTED

As we can see the myth of ?Hemcrete can replace standard concrete? simply isn?t feasible. We are not saying hempcrete has no practical use. Many people are interested in incorporating it into their buildings, remodels, etc. In the context of the myth though, hempcrete just doesn?t offer the same critical performance as standard concrete nor is it cost competitive. The cost part is a primary issue both from the concrete producers side of minimizing production costs and the opportunity cost to farmers. In the case of the farmer, all of the costs would need to be shifted before it makes any sense and once transport is factored in, the revenue from hemp for hempcrete is not worth the amount of effort.

Hempcrete may have increased environmental benefits, sure, but when building structures, the most important aspect is safety and ensuring the structure will actually support itself, something hempcrete cannot guarantee (when looking to replace standard concrete given the current accepted mix design). One could argue that hempcrete can be used if there are frames and other load bearing systems but that doesn?t apply to standard concrete so that does count in this analysis.

Now, in another instance, hempcrete can be used as an insulator which has some benefits but that is a myth for another day?