A Guide to Sound-dampening Gypsum Board, a.k.a., ?Soundproofing Drywall?

If you?re planning a construction project where noise control is important, you might be facing the choice between using multiple layers of standard drywall and buying very expensive ?soundproofing drywall.?

Does soundproofing drywall work and is it worth the cost? The short answer is yes: soundproofing drywall works.

But the question of value for money depends on your noise control needs, construction requirements, labour costs, overall budget, and the existing site conditions.

Installing a partition twice is always more expensive than doing it right the first time.

Deciding if soundproofing drywall is worth the high cost depends on the consequences of project failure and the overall budget available, among other key considerations.

Deciding if soundproofing drywall is worth the high cost depends on the consequences of project failure and the overall budget available, among other key considerations.

This article summarizes what types of soundproofing drywall are available on the market, the costs, and what to consider before choosing to buy it. We also provide a short backgrounder on how noise control gypsum board works for those who are interested in the technical details behind the products.

Types of soundproofing drywall on the market

There are three major manufacturers that hold patents on soundproofing drywall. They make several useful variations for construction and renovation projects, and these are outlined below.

QuietRock

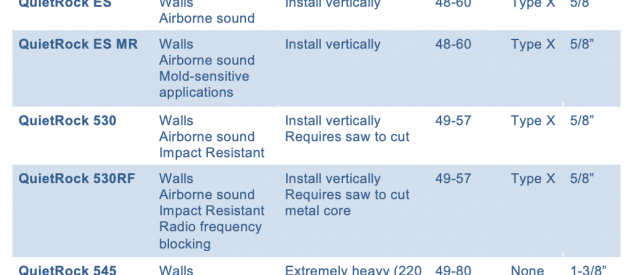

Pabco Gypsum owns QuietRock, which sells sells seven types of soundproofing drywall under the brand. These include:

- QuietRock 510, a 1/2″ thick board

- QuietRock ES and the mold resistant variant QuietRock ES MR, both of which can be scored and snapped like regular drywall, are fire rated and 5/8″ thick.

- QuietRock 530, which is impact resistant and has a radio frequency, ground-able version called QuietRock 530 RF

- QuietRock 545, which is studio grade, 1-3/8″ thick and is arguably the most advanced acoustic drywall available

- Pabco Gypsum Sound Curb, which is 3/4″ thick, is designed for ceilings, and has both sound and impact noise ratings.

A summary table with the features of each one is included below.

QuietRock is owned by Pabco Gypsum and sells seven different types of sound dampening drywall

QuietRock is owned by Pabco Gypsum and sells seven different types of sound dampening drywall

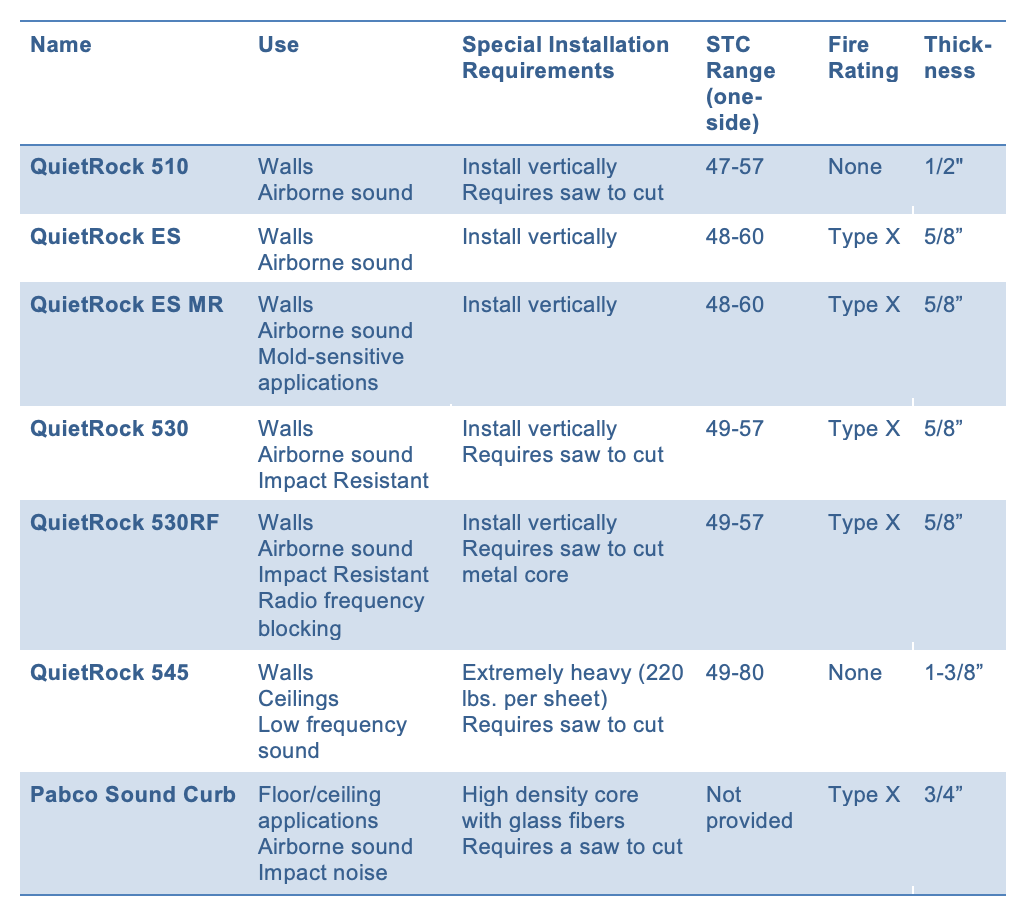

CertainTeed

Owned by Saint Gobain, CertainTeed markets one major type of soundproofing drywall Called SilentFX QuickCut, which is 5/8″ thick, can be scored and snapped, and is also fire-rated.

SilentFX QuickCut drywall is manufactured and sold by CertainTeed

SilentFX QuickCut drywall is manufactured and sold by CertainTeed

National Gypsum

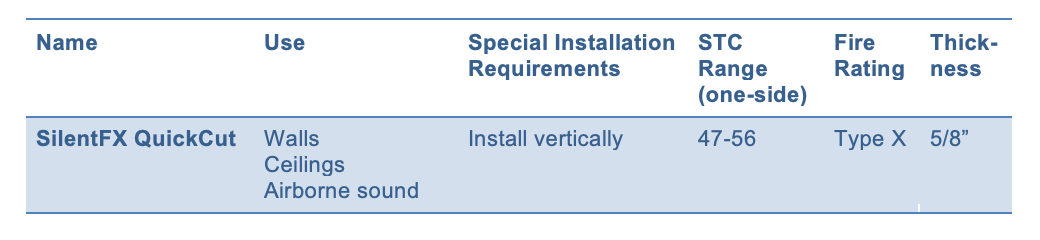

Another player in the soundproofing drywall market is National Gypsum, which markets a line of products called Gold Bond SoundBreak XP, in four variations.

- SoundBreak XP 1/2″ Wallboard

- SoundBreak XP 5/8″ Wallboard, which is fire rated

- SoundBreak XP Retrofit Board which is thinner and designed to be layered onto existing drywall

- SoundBreak XP Ceiling Board, which is 3/4″ thick and designed for ceiling installations, and is fire-rated

National Gypsum sells four sells four different products under the Gold Bond SoundBreak XP brand

National Gypsum sells four sells four different products under the Gold Bond SoundBreak XP brand

Is soundproofing drywall worth the cost?

Overall, the value generated by using soundproofing drywall can far outweigh the cost, but it depends on project scope, design requirements, timeline, and labour costs.

The question of value for money is also closely tied to the consequences of project failure. Installing a partition twice is always more expensive than doing it right the first time.

In relatively simple assemblies with moderate noise control requirements, using a simple double-drywall specification can be more cost effective than using soundproofing drywall.

But when noise control requirements exceed STC 55, specifying soundproofing drywall can lead to lower labour costs than installing multiple sheets of drywall on each side of the wall.

Soundproofing drywall can also increase available floor space, because the overall depth of the wall design can be thinner. In medium-to-large sized projects with many partitions into small offices or rooms, using soundproofing drywall will increase usable floor space because each wall can be relatively thin compared to standard noise control designs with multiple drywall layers on each side.

When correctly installed, soundproofing drywall will outperform the old-school methods of doubling or tripling up the drywall layers. Most importantly, using it is also far more reliable than using a DIY method such as adding a viscous compound like GreenGlue or QuietGlue manually between two drywall sheets, which requires a highly skilled crew that won?t make mistakes during construction.

Acoustic performance requirements and project timelines are two of the many factors to consider when deciding whether or not to include soundproofing drywall in your construction or renovation project.

Acoustic performance requirements and project timelines are two of the many factors to consider when deciding whether or not to include soundproofing drywall in your construction or renovation project.

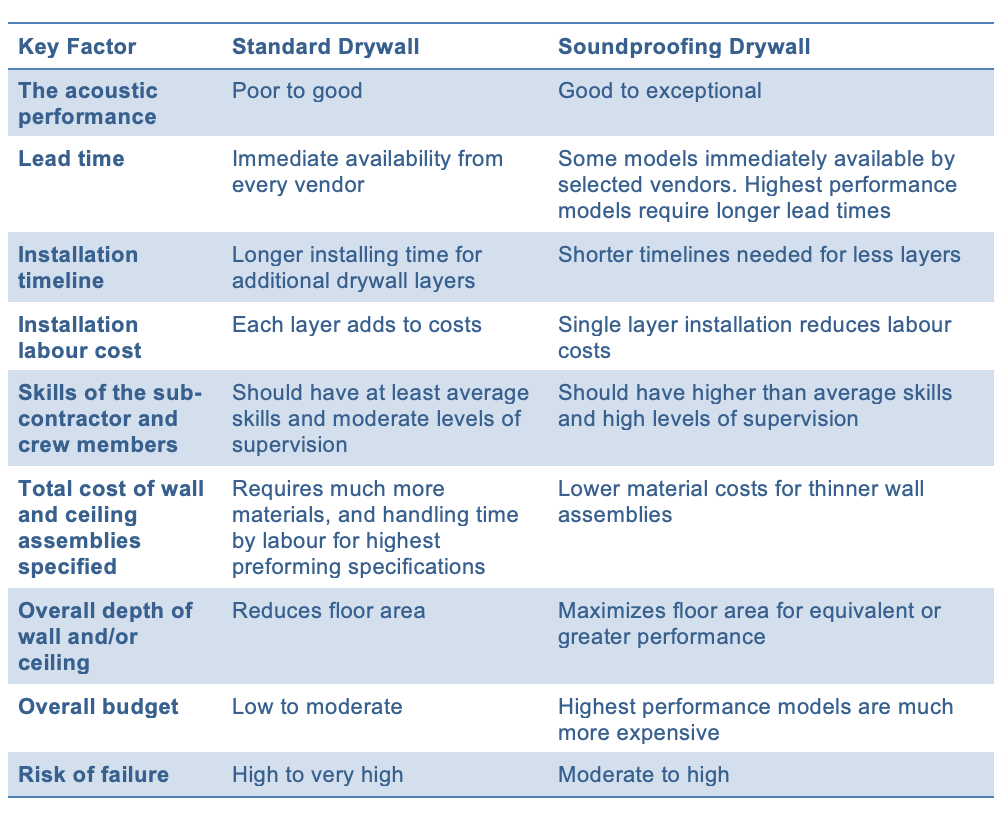

Factors to consider when choosing between regular and soundproofing drywall

Overall, there are many factors to consider before making a final decision. These include:

- The acoustic performance requirements (must have vs. nice to have)

- Lead time available to purchase materials

- Installation timeline to complete the project

- Installation labour costs

- Skills of the sub-contractor and crew members available

- Total cost of wall and ceiling assemblies specified

- Overall depth of wall and/or ceiling (and resulting usable floor spaces or leasable floor areas and/or ceiling heights)

- Risk tolerance for failing to meet the acoustic performance requirements

- Overall budget available.

How soundproofing drywall compares to standard drywall installations

Soundproofing drywall will outperform a standard drywall assembly by about 5 STC points when all other design elements are identical. A five STC point difference can reduce sound transmission enough to cross the threshold of annoyance or privacy in a medical office, for example.

You could match the soundproofing drywall assembly with additional layers of 5/8? Type X drywall instead, but this results in increased labour and material costs, additional installation time, and an increase in overall width of the wall or ceiling.

Comparing wall assemblies and methods

The following table summarizes some key considerations when deciding whether or not to use soundproofing drywall in your construction or renovation project.

Key factors in choosing sound-dampening drywall versus standard drywall

Key factors in choosing sound-dampening drywall versus standard drywall

It?s not just the drywall that matters

It?s also crucial to understand that sound dampening gypsum board works when it is installed as part of a noise control wall assembly. In other words, it?s not just about the drywall, it?s about the whole system ? whether you choose soundproofing drywall or not.

Walls and ceilings will meet acoustic performance targets when the specifications and installation meet key design requirements. These include:

- The wall framing material (the quality and size of metal or wood)

- The spacing of the wall studs or floor joists (16 inches or 24 inches)

- Dampening materials or technology placed between the framing and building structure (e.g., resilient layers or decoupling clips and channel to stop structural reverberation)

- The size of the air cavity within in the wall or ceiling (those with nil or small air cavities perform poorly)

- Insulation material used, the density and overall depth of it within the wall (quality and size matter)

- The amount of openings in the wall/ceiling for electrical outlets and lights, etc. (the less the better it is for acoustic performance)

- The use of acoustic sealant and putty to seal openings, irregular gaps, weak areas, flanking paths, and perimeter gaps.

- The correct installation of the gypsum board (for example, not resting on the floor or pressed against ceiling boards)

The overall result depends on the amount of attention paid to these details during design and specification, as well as during installation and inspection.

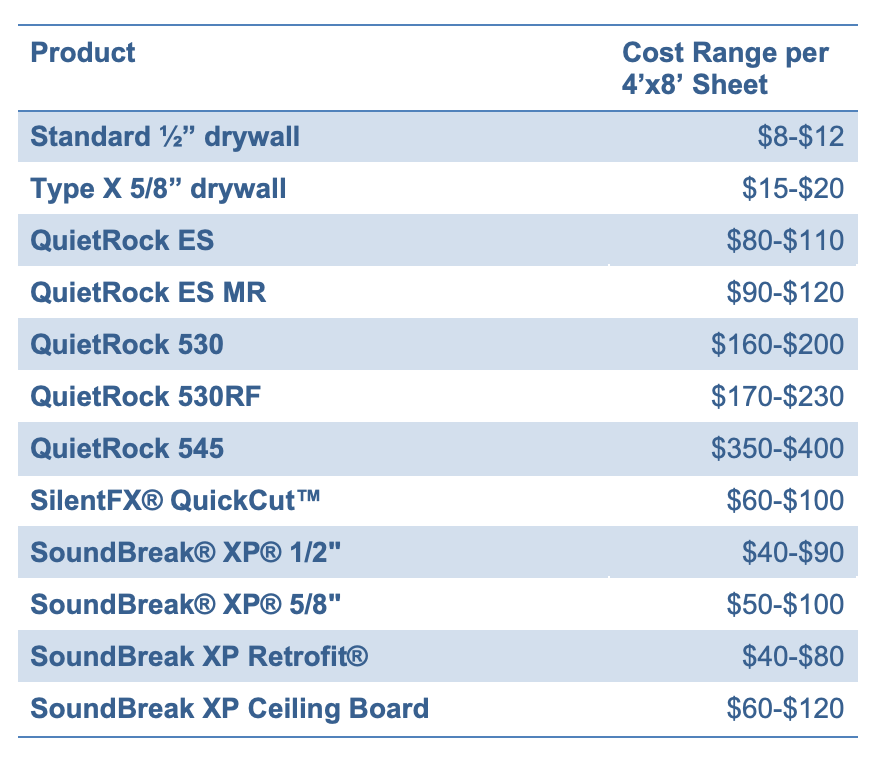

Soundproofing drywall costs

Pricing varies widely depending on your location and how far your project is from the distributors who carry the product. Prices can range from 4x to up to 15x the cost of standard 1/2″ or 5/8″ Type X drywall.

Sound-dampening gypsum board is mostly carried by specialized distributors, and it?s recommended to contact the vendor to obtain obtain current prices. The costs cited below are sample prices only and refer to the US and Canadian markets. Delivery and sales taxes, if applicable, are extra and will add to the costs cited below.

Pricing on soundproofing drywall varies widely depending on your location and proximity to distributors who carry the products.

Pricing on soundproofing drywall varies widely depending on your location and proximity to distributors who carry the products.

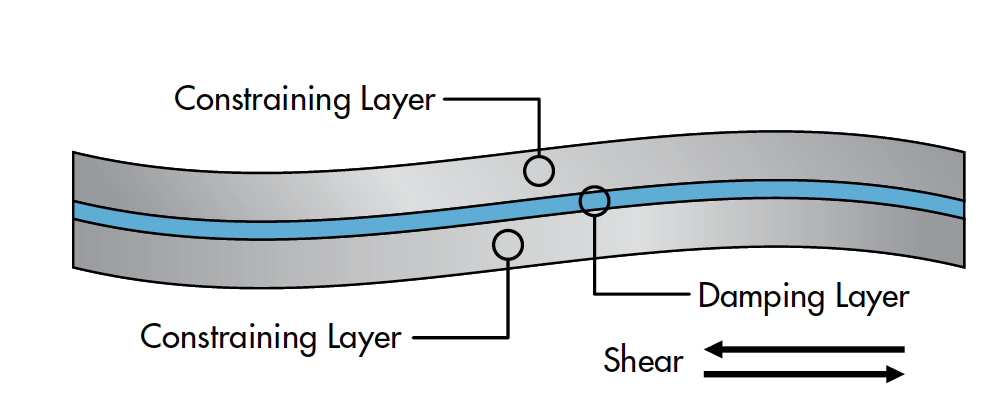

How it works: a short backgrounder on soundproofing drywall technology

There are several types and grades of soundproofing drywall that use innovative and patented methods to dampen sound. Without going into a full backgrounder on noise control, it?s helpful to know the basic physics of sound to understand how sound-dampening drywall works.

Although invisible, sound waves have contain energy that transmits not only through the air, but also through most types of solid and liquid materials. Sound waves in one room can vibrate a wall enough to cause that wall to generate new sound waves in an adjacent room.

Most commercial and residential demising walls, ceilings, or floor structures will hold back some sound energy, but a lot of it will be transmitted into an adjacent room or exterior area quite easily. Only an extremely massive wall is capable reflecting the energy from intense sound waves to make them inaudible in an adjacent area. Picture a bunker made with three feet of solid concrete, 500 lb. doors, and buried far underground and you get the idea of what it would take to make the sound of a chainsaw inaudible.

Soundproofing drywall works by taking a different approach: dampening the sound waves by converting them into a different energy form: thermal energy, or simply put, heat. Depending on the manufacturer, noise control gypsum boards use patented technology made with a proprietary polymer sandwiched between two or more layers of gypsum. The polymer moves when vibrated by sound waves, causing friction with those same sound waves and converting that energy into heat.

Most soundproofing drywall uses constrained layer damping to convert sound waves into other forms of energy and prevent transmission through the gypsum board

Most soundproofing drywall uses constrained layer damping to convert sound waves into other forms of energy and prevent transmission through the gypsum board

When installed correctly, the design of the noise control gypsum board causes enough friction to convert acoustic energy that hits it into thermal energy, instead of causing the whole wall to reverberate and transmit sound waves into the next room.