Two popular filaments, but different features. In the rapidly developing industry that is 3D printing, sometimes it?s hard to follow the trends. Check our PETG vs. PLA comparison and learn about the main differences and sample applications.

Sample PLA prints you can put on your desk. Left: pencil holder; right: laptop stand.

Sample PLA prints you can put on your desk. Left: pencil holder; right: laptop stand.

PLA was always the go-to basic filament and is still recommended when you start your journey with 3D printing. The rising popularity of PETG makes some people switch to the latter material. The question is: should you? Hopefully, after you read this article you won?t have any problem with choosing a filament for your next project.

PLA (or polylactic acid) is one of the most popular thermoplastics for 3D printing due to its wide availability and color range. It?s cheap, easy to print, and doesn?t emit dangerous fumes. Because of its printability and versatility, it?s often recommended for inexperienced users. PLA is also partially biodegradable and doesn?t require a closed printing space (meaning that almost any FDM 3D printer on the market will do well with the material).

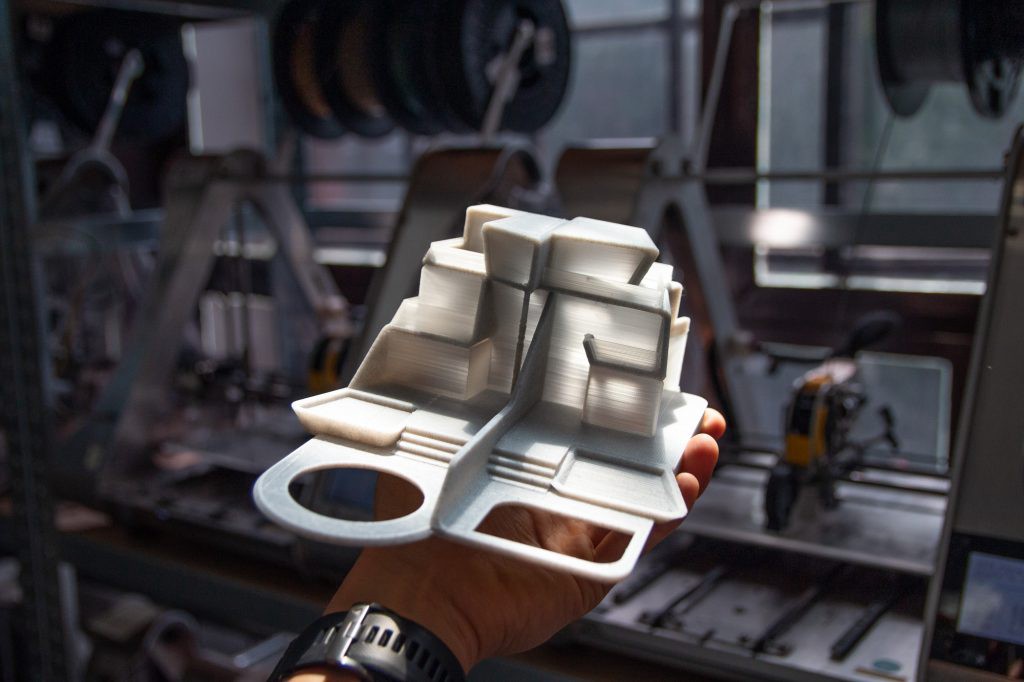

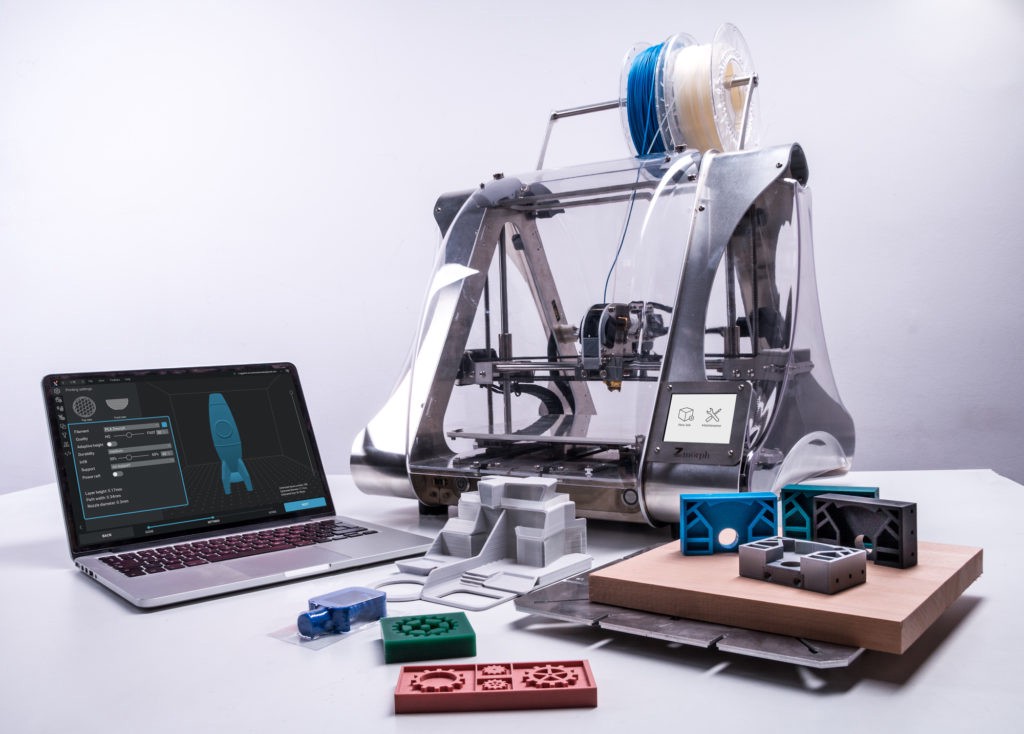

Sample model 3D printed with PLA on ZMorph Multitool 3D Printer using Dual Extruder.

Sample model 3D printed with PLA on ZMorph Multitool 3D Printer using Dual Extruder.

PET (polyethylene terephthalate) is a thermoplastic polymer used for drink bottles or sailcloths. Mixed with glycol (hence the ?G?) exhibits good 3D printing features. PETG filament is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties. PETG combines ABS durability and PLA printability, and it comes as no surprise that it?s frequently chosen by professionals seeking a reliable filament for their projects.

PETG electronics casing.

PETG electronics casing.

PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

3D printed PETG headband for face shield.

3D printed PETG headband for face shield.

PETG vs PLA ? Technical Data

Below you?ll find the most important technical properties for PETG and PLA.

PLA

Vicat softening temperature: 55 C (131 F)

Heat deflection temperature: 55 C (131 F)

Impact strength: 16 kJ/m2

Flexural modulus: 3500 MPA

Density: 1.24 g/cm

Melt Flow Index: 6 g / 10 min

PETG

Vicat softening temperature: 85 C (185 F)

Heat deflection temperature: 70 C (158 F)

Impact strength: 11 kJ/m2

Flexural modulus: 1880 MPA

Density: 31.27 g/cm3

Melt Flow Index: 11 g / 10 min

PETG vs PLA Temperature for 3D Printing

Because the two filaments are different and have distinctive technical properties, you should use different printing temperatures for PLA and PETG. Here?s the main difference between PLA and PETG:

PLA

- Printing temperature: 200?230 C

- Bed temperature: 60 C

- Printing space: Open

PETG

- Printing temperature: 230?250 C

- Bed temperature: 60?80 C

- Printing space: Closed

This tail lamp was 3D printed using PETG filament.

This tail lamp was 3D printed using PETG filament.

If you want to learn about how to 3D print with PLA or PETG, how to set up your machine or slicer, check our other articles:

PLA: 3D Printing Materials Overview ?

PET-G: 3D Printing Materials Overview ?

PLA figurines showcasing the Voxelizer supports.

PLA figurines showcasing the Voxelizer supports.

PETG and PLA Prices

There is a slight difference in prices when it comes to PLA and PETG. Also because of the popularity, PLA is slightly cheaper. They both come in a wide variety of colors, although it?s easier to find PLA in the desired color. On the other hand, it?s more common for PETG to be transparent.

In our online store, you can find PLA in the price of $34 / kg. PETG costs $39 / kg.

PET-G ZMorph 3D printing filament.

PET-G ZMorph 3D printing filament.

What?s the Difference Between PETG and PET?

You may encounter two options ? PETG (sometimes written as PET-G) and PET. The ?G? stands for glycol ? a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that?s easy to scratch. That being said, the chemical properties of PETG are far better for 3D printing despite some minor disadvantages.

PLA vs ABS vs PETG

Another popular 3D printing filament is ABS, which is often used as an alternative to PLA or PET. It?s much more durable than PLA and frequently used for industrial applications.

Compared to PETG, ABS is more prone to warping and requires higher printing bed temperatures (100 C for ABS, and 60?80 C for PETG). Another advantage of PETG over ABS is that it emits much fewer fumes, a feature that you will appreciate after 3D printing with ABS.

3D printed ABS.

3D printed ABS.

You can read more about the differences between ABS and PLA here, and a comprehensive comparison between PETG and ABS is coming soon.

Sample PETG and PLA Applications

It?s time we talk about where PLA and PETG are to be used. With different features, these two materials have miscellaneous applications.

PLA laptop stand.

PLA laptop stand.

PLA is designated for early-stage prototyping, showcase models, and quick fixtures, whereas PETG can be applied in more industrial operations. Namely, mechanical components, electronic devices housings, transparent elements, etc. Thanks to the water resistance, PETG can be used also to 3D print containers and bottles. PLA doesn?t go well with moisture and may start to decay when exposed to water.

PETG garden hose connectors.

PETG garden hose connectors. PETG garden hose connectors.

PETG garden hose connectors. PLA pencil holder.

PLA pencil holder.

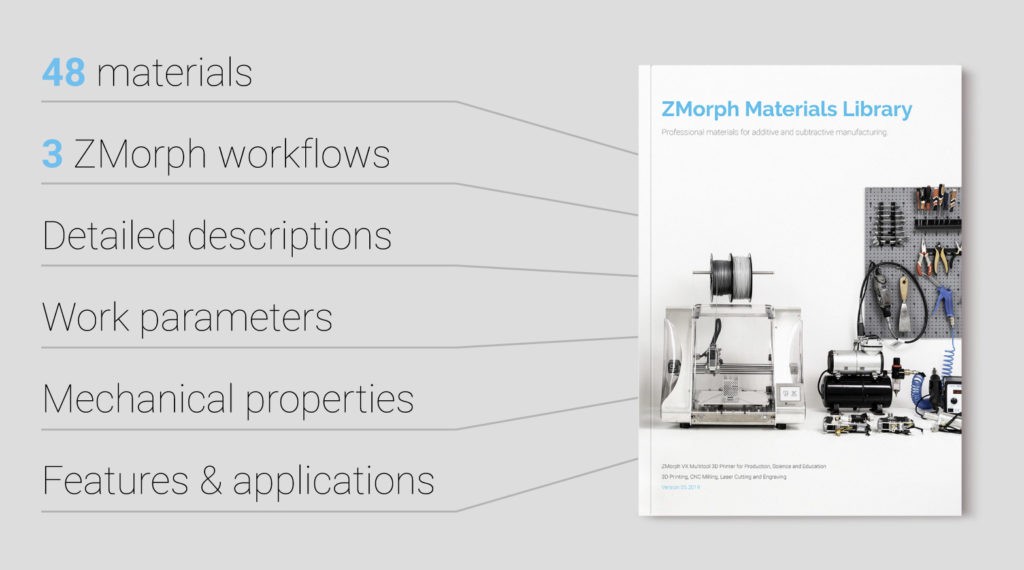

Discover More Materials for 3D Printing

Now that you know the main differences between PETG and PLA, you may want to learn about other materials for 3D printing. Because ZMorph VX supports most of the filaments available on the market, we prepared the ZMorph Materials Library where you can find out about other materials ? their main features, sample applications, and, most importantly, the technical data. It?s all available online for free.

3D Printing with ZMorph VX

ZMorph VX Multitool 3D Printer is designed to work with a vast array of available filaments including both PLA and PETG. We make sure that the workflow is as simple as possible.

Use Voxelizer software to slice the STL file and send it to ZMorph VX. The default presets prepared for our branded filaments ensure the outcome will be perfect with the first try if you follow the ZMorph workflow.

ZMorph VX All-In-One 3D Printer

ZMorph VX All-In-One 3D Printer