Sustainability is a topic that concerns every aspect of our life.In the design industry, this ranges from sustainable interior design products to sustainable building materials.

What are sustainable building materials?

There is no single answer to this question. But above all, a sustainable building material is one that:

- Generates less waste

- Uses renewable raw materials

- Is more durable

Research is currently moving in all these directions.So let?s discover some building materials that showcase the potential of sustainable and circular design!

The new generation of concrete

One of the most widely used building materials is certainly concrete. To give an idea of scale, the Guardian states that

?All the plastic produced over the past 60 years amounts to 8bn tonnes. The cement industry pumps out more than that every two years.?Cit. Jonathan Watts

Concrete has undeniable sturdiness advantages, but these are definitely paired with some disadvantages. Some considerations about the sustainability of concrete include huge amounts of water used for production, air pollution and overexploitation of natural resources coming as consequences of quarries and many more?

There is no fast and easy solution here, but the following projects are all good food for thought!

CIRCULAR DESIGN: FROM WASTE TO BRICKS

Project by: StoneCycling

Besides making a lot of buildings, we also demolish plenty. And where do all the demolition debris go? Are those just waste?Certainly not in a circular design perspective, where they should be looked at as a resource and transformed into something useful.

This is exactly what StoneCycling has done, turning demolition debris into waste-based bricks that can be used in construction again! Their WasteBasedBricks collection includes various textures and colours that open to all sorts of creative pairings!

Different types of demoliton debris. Credit: StoneCycling

Different types of demoliton debris. Credit: StoneCycling

External building covering with WasteBasedBricks. Credits: Urban Echoes ? Photo by Stijn Poelstra

External building covering with WasteBasedBricks. Credits: Urban Echoes ? Photo by Stijn Poelstra

Internal wall cladding with WasteBasedBricks. Credits: StoneCycling

Internal wall cladding with WasteBasedBricks. Credits: StoneCycling

CONCRETE FOR BIODIVERSITY

Project by: ISDI-Indian School of Design and Innovation

Another disadvantage of concrete is that it?s pretty distant from all what is natural and it ?takes space away? from plants and greenery.But there?s a new sustainable building material at the horizon that could build a bridge and actually foster biodiversity.Obtained from a mix of soil, cement, charcoal and organic luffa fibres (yes the same of bath sponges!), the Green Charcoal bio-bricks are very porous bricks where plants can grow. Essentially, these bricks can work as a backdrop for a naturally grown green wall!

The presence of hollow pockets also makes these bricks able to cool interior spaces down. In short, they help with indoor air quality while introducing a biophilic element!

Credit: ISDI (via Medium)

Credit: ISDI (via Medium) Credit: ISDI (via Medium)

Credit: ISDI (via Medium)

SELF-HEALING CONCRETE

Project by: Technical University Delft and Basilisk Concrete

Another one of the top disadvantages of concrete is that is cracks.But what if it could repair itself?Biofabrication is a very promising path creating beautiful and eco-friendly living materials.

In the case of concrete, researchers are experimenting with a sort of living concrete, that is essentially equal to the standard one, but has bacteria added into the mix.These bacteria wake up when they come in contact with water and oxygen (aka when a crack occurs). They then start producing limestone and essentially heal the crack, leaving only a slight scar on the surface! Is this not mind-blowing?

Credit: EPO-European Patent Office

Credit: EPO-European Patent Office The scar left when self-healing is complete. Credit: Basilisk Concrete

The scar left when self-healing is complete. Credit: Basilisk Concrete

Biobased building materials

Besides living concrete, other biobased and sustainable construction materials are coming up. The thing they all have in common is that they?re made of organic ingredients. And ? in some applications in particular ? they would be a brilliant alternative to concrete!

HEMP CONCRETE

Project by: Dun Agro

Mix hemp fibres with natural glue and some water, and you?ll get a new building material! Hemp concrete (or Hempcrete) is a sustainable option that also retains all the qualities we look for in building materials. It is sturdy, has good thermal & acoustic insulation qualities and it is fire resistant.

One of its biggest sustainable properties is that it?s CO2 negative, namely it absorbs more CO2 than the one it emits!

Credit: Dun Agro (via Material District)

Credit: Dun Agro (via Material District) Hemp concrete internal walls. Credit: @cobbledtogether (via Instagram)

Hemp concrete internal walls. Credit: @cobbledtogether (via Instagram)

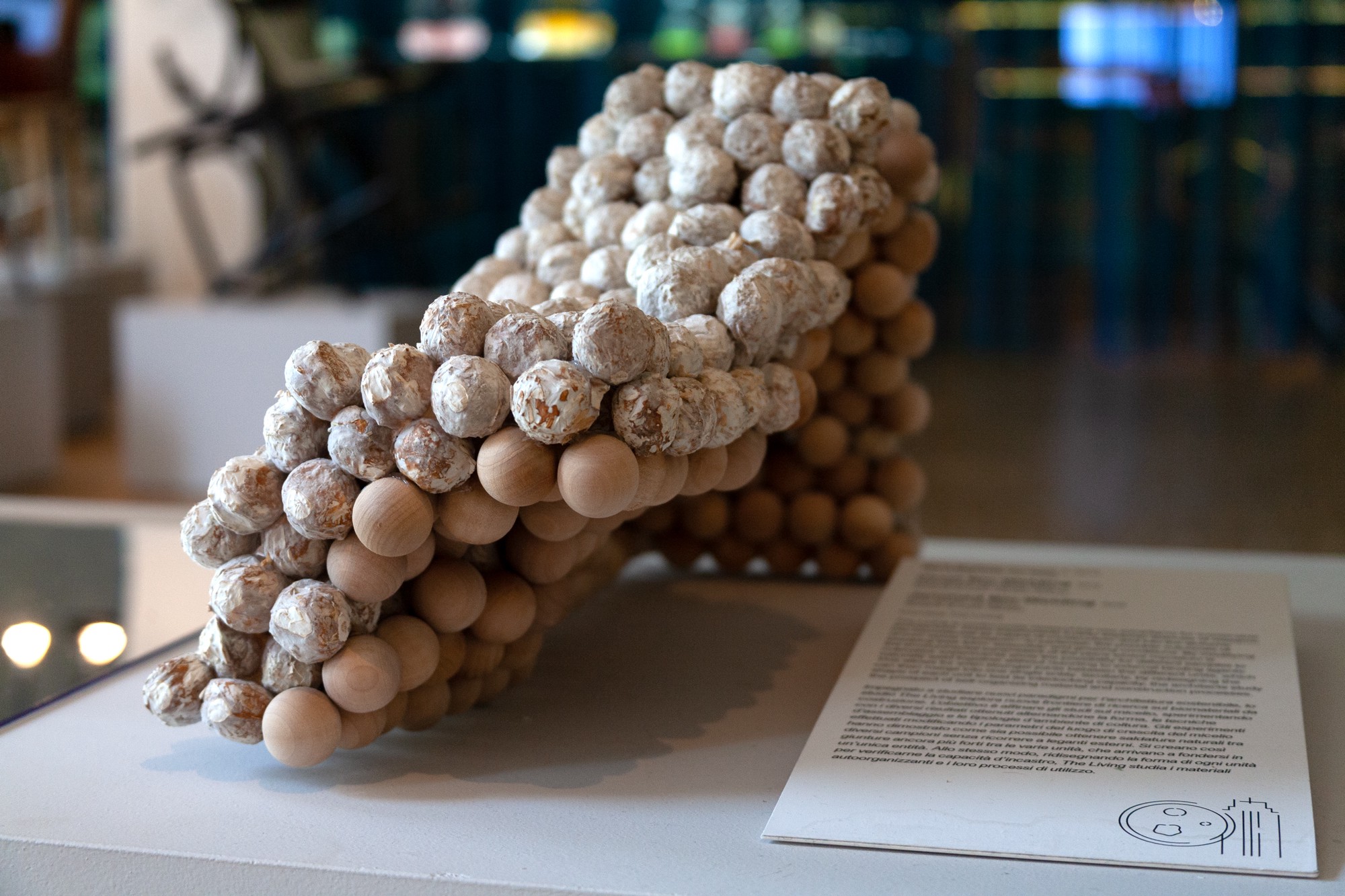

ORGANIC CIRCULAR DESIGN BRICKS

Project by: The Living

Hy-fi bricks are a mix of circular design and biofabrication. They make use of agricultural waste (corn stalks) and mix it with mushroom mycelium into brick-shaped moulds. Mushrooms will take a few days to grow, resulting in fully organic bricks that can be composted at the end of their life!

Credit: Larafge Holcim Foundation

Credit: Larafge Holcim Foundation Tower made with Hy-fi bricks. Credit: Larafge Holcim Foundation

Tower made with Hy-fi bricks. Credit: Larafge Holcim Foundation

BRICK WITHOUT MORTAR

Project by: The Living

Similarly, mushroom mycelium has been used to grow bricks that naturally weld together without needing any mortar-like substance. Voxel bio-welding ensures an extremely strong joint, because the different bricks essentially become one single thing!I?ve seen these exposed at Broken Nature as an example of restorative design and I must say they look as impressive in real life!

Credits: DforDesign

Credits: DforDesign

Sustainable design can take many different forms and it?s extremely inspiring to explore them all!

For more about sustainable options for interiors, you?re welcome to check out SforSustainable? the sustainable interior design resource where I curate a selection of eco-friendly products from furniture to finishes!

Originally published at dfordesign.style.