Racecars are really cool. But how do I design formula-style racecar?

People have asked me how to design a racecar and how to start a Formula SAE (FSAE) team at their universities. The goal of this article is to help those individuals jump-start their FSAE adventures.

As a little bit of background, I was a suspension design engineer on the UC Berkeley Formula SAE Team for a little over two years. And I had a part in the 2015 and 2016 racecars. In 2016, the team placed 11th out of 70 at the Formula SAE Lincoln competition.

Me in the Berkeley Formula SAE Team?s 2016 racecar at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

Me in the Berkeley Formula SAE Team?s 2016 racecar at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

There is a really great 29-minute video of Claude Rouelle ? a design judge for FSAE ? giving advice for FSAE teams. If you?d like, give it a listen. Then come back here for a summary, my commentary, and cool pictures!

1. Know the Rules

It?s critical that you read the rules. Download the official set of rules at fsaeonline.com. (These rules are specific to Formula SAE in North America. If you intend on competing in another competition like Formula SAE Electric, Formula Student Germany, etc., be sure to read the correct set of rules.) Set aside an afternoon to read the rules. If you?re not sure what something means, Google it! Someone has probably already asked that very same question.

2. Brainstorm

Your first goal is to build an A-team and a C-car. As the team improves year-over-year, you will make a car that is better and better. Eventually you will have an A-team and an A-car.

It?s impossible for a C-team to make an A-car.

To build an A-team, brainstorm the characteristics of a perfect team. While creating the list, think of things like:

- How will conflicts be resolved?

- What do you hope to learn from each other?

- How will projects be managed?

- etc?

Once you figure out what the perfect team looks like, have every team member pledge to try their best to express all of the characteristics.

Nothing is impossible

To build an A-car, brainstorm the characteristics of a perfect car. This should be approximately a three-hour brainstorm. Go into this brainstorming session with the idea that nothing is impossible. Write down everything, no matter how difficult or crazy it seems.

Once you have this list of perfect racecar characteristics, come back to the list (a different day) and order the list in order of priority. High priority means that this feature is a must-have feature. Things that could affect priority could include feasibility, cost, and impact to points at competition. Priority may change during the Concept and Simulation Phase.

3. Know the Correct Order of Operations

Just like math has an order of operations, designing a racecar also has an order of operations: Concept, Simulation, Design, Manufacturing, and Assembly.

3.1. & 3.2. Concept and Simulation Phase

Many teams complete the Concept and Simulation Phase during summer or early fall. You want to target being done by September.

Milliken?s Race Car Vehicle Dynamics is widely regarded as the FSAE Bible

During Concept and Simulation, figure out what you want your car to have:

- What engine do you run?

- What wheel size?

- Tires?

- Gearing?

- Suspension?

- Aero package?

- etc?

There is no ?perfect? combination of parts, but there are quantitative reasons why some characteristics are more popular than others. To understand why, read Milliken?s Race Car Vehicle Dynamics. RCVD is widely regarded as the FSAE Bible. Another essential read is Carroll Smith?s Tune to Win: The Art and Science of Race Car Development and Tuning.

Use a lap simulator (a tool to help you calculate a laptime on a hypothetical race track) to measure the effect of different vehicle specifications. You have a lot of variables that you can change. So be patient, this could take a month or two.

Order of simulations:

- Simple one-mass simulation around a given racetrack. The goal of this step in the simulation process is to figure out a starting point for overall vehicle weight.

- Tires. This is a huge can of worms: What tire compound do you use? What happens with toe and camber? Tire pressures? Slip angles? From this you can determine your mass distribution, power need, vehicle kinematics, and if you need downforce. Your team must absolutely be a part of Milliken?s FSAE Tire Test Consortium (TTC). The TTC has all of the data necessary for you to make an informed decision on vehicle specifications. (As a potentially helpful starting point, a significant number of teams tend to run the Hoosier R25B tire compound.)

Optimum G offers OptimumKinetics at a discounted price to student groups. Learn more about student licenses for OptimumKinetics here.

The end-goal of Concept and Simulation is a list of vehicle specs:

- vehicle weight (and weight distribution, center of mass),

- wheelbase and track width,

- power unit (and power and torque targets),

- downforce targets (for various aerodynamic parts, if you decide to run an aero package),

- etc?

You must have a full list of vehicle specs. Only then can you start designing the car.

3.3. Design Phase

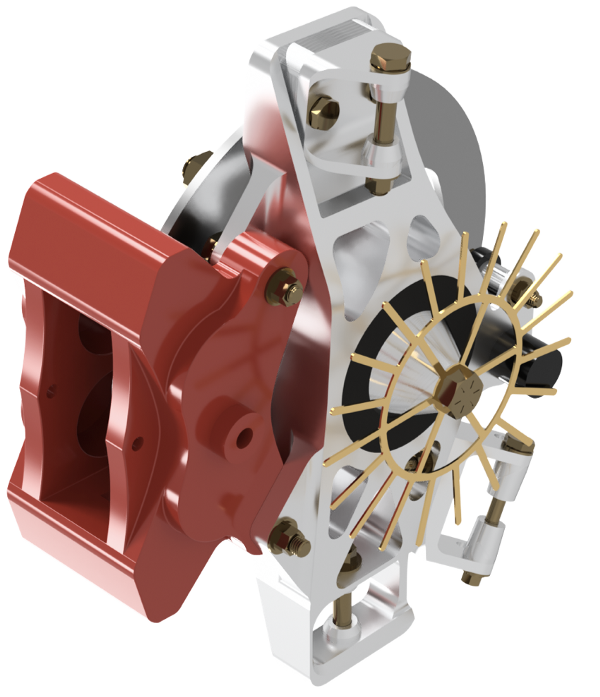

Render of the Berkeley Formula SAE Team?s 2016 racecar?s front upright. Berkeley, CA. Dec. 2015.

Render of the Berkeley Formula SAE Team?s 2016 racecar?s front upright. Berkeley, CA. Dec. 2015.

Once the team is aligned on the list of vehicle specs, Design can begin!

Use 3D Computer Aided Design (CAD) to design the car. This should take about three months. The end of Design should land you in December.

Most universities will have CAD program licenses available to students. If for some reason your university does not (or the free student licenses only offer limited functionality), you can reach out to most CAD software makers for licenses. In your email, be sure to mention that you represent your university?s FSAE team and that your team requires X number of licenses. Often times, they?ll give you licenses in exchange for putting their company logo on your racecar. For example, SolidWorks can be easily obtained with the submission of a simple form. Get more information here.

My CAD program of choice is NX. SolidWorks and CATIA are also popular with FSAE teams.

At a minimum, all of the mechanical parts should be modeled in CAD. You want a reliable racecar. To do this, you simulate your parts with Finite Element Analysis (FEA) to make sure that your parts will not break. Start off with robust parts with large safety factors. And as the team gains more experience throughout the years, use your best engineering judgement to decrease the safety factors.

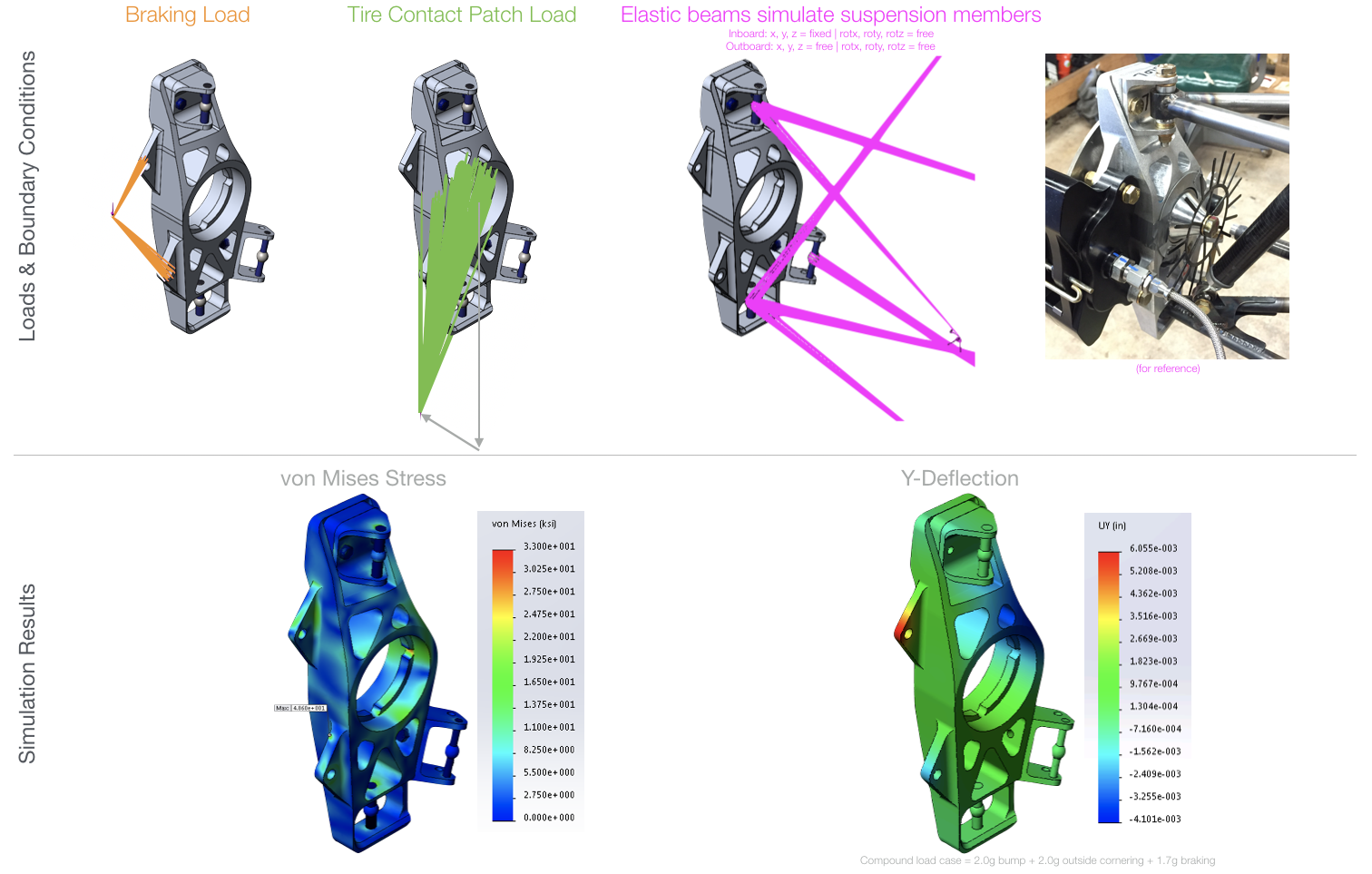

Setup and results of a finite element analysis of the front upright. Berkeley, CA. Nov. 2015.

Setup and results of a finite element analysis of the front upright. Berkeley, CA. Nov. 2015.

Don?t forget fatigue and modal analysis. Understanding the stiffness is also important for some parts.

Be sure to back up your simulations with good ole fashioned hand calculations. The FEA results could be lying to you.

If your team decides to run an aero package, be sure to run Computational Fluid Dynamics (CFD) simulations. A wing is only useful if it creates a significant amount of downforce.

My FEA and CFD program of choice is ANSYS.

Also make sure to Design For Manufacturability and Design For Assembly (DFM and DFA). You must be able to actually make and assemble your parts. I can?t tell you how many times I?ve designed a part, realized that it was impossible to make, and had to redesign it.

3.4. & 3.5. Manufacturing and Assembly Phase

Manufacturing of the front uprights. Berkeley, CA. Feb. 2016.

Manufacturing of the front uprights. Berkeley, CA. Feb. 2016.

Now that the racecar is designed, you?ll need to make all of the parts. Manufacturing and assembly should take about three months, putting you at March.

Create detailed engineering drawings for all of the parts. The method of manufacturing the parts should have been in the back of your head while you were designing the parts. Make sure you use tolerances that you?re sure that you can hit. But also make sure that the tolerances are OK for the function of your parts and assemblies. You may need to do some tolerance analysis or dimensional variation analysis.

Some multi-part parts like A-arms or the chassis may need welding fixtures or jigs. Be sure to put thought into those, since bad fixtures/jigs result in out-of-spec parts.

Once parts are made, and they?re put together, you should have something that resembles a racecar!

4. Testing, Testing, Testing

You need to run your racecar, a lot. The instant your racecar is done being assembled, the team should be running the car. Run the car all the way until competition.

A team with a world-class driver and a crap racecar will place higher than a team with a crap driver and a world-class racecar

Driver training is the single largest contributor to gaining points at competition. A team with a world-class driver and a crap racecar will place higher than a team with a crap driver and a world-class racecar.

The best way to improve your drivers? skills is to give them as much seat time in the racecar as possible. Not only will they improve their driving skills, but they will also (and more importantly) become more familiar with how the racecar handles. This improves driver confidence and ultimately driver performance.

Don?t run the racecar just for the sake of running the racecar and getting driver seat time. While you are running the car, run tests to validate your design decisions. For example, if your team is running an aero package, conduct some experiments to measure how much downforce the wings are actually producing, and compare to your CFD simulations.

Also, set up cone courses and run the car in different configurations to see which configuration is the fastest. For example, changing spring rates and damping rates are cheap and easy ways to tune the racecar.

Again, I want to reemphasize that driver training is the most important factor for gaining points at competition (and finishing endurance). Second is racecar tuning. Last is everything else.

As a side-note, you can conduct driver training before the car is running by going to go-kart places or by playing realistic racing simulator games like rFactor 2. The UC Berkeley Formula SAE Team used both with great effect in 2016. Now that virtual reality gaming is more common, racing simulators have become even more useful.

5. Competition

The car during the autocross event at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

The car during the autocross event at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

So you have a racecar and it?s ready to go to competition. That?s really exciting!

One thing that teams often overlook is competition logistics. Plan for everything:

- How do you transport the racecar to competition?

- What about the giant toolbox?

- Do you have spare parts for the car?

- Spare tires?

- Spare rain tires?

- How are you getting to competition?

- Where will you be sleeping?

- Will you be sleeping?

- Where do you get food and water? (Please don?t forget to stay hydrated!)

- etc?

Be prepared to fix a lot of things for tech inspection.

For the design event, come to competition prepared with all of your design decision and testing one-pagers organized in a binder. Include all of your data visualizations (graphs and plots) and engineering drawings. It?s extremely useful to rehearse your talking points.

If your team has been running the car since March, you should have no problems for the dynamic events (acceleration, skidpad, autocross, and endurance). Though, don?t become complacent and lazy. Unexpected things happen?unexpectedly.

Remember, FSAE is a team effort

Finally, support your drivers. They?re under incredible pressure to not crash the racecar. Remember, FSAE is a team effort.

Berkeley Formula SAE Team photo at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

Berkeley Formula SAE Team photo at Formula SAE Lincoln. Lincoln, NE. Jun. 2016.

Conclusion/TL;DR

These are steps to design a Formula SAE car:

- Read the rules.

- Figure out what the perfect team is. Figure out what the perfect car is. Make lists.

- Use a lap simulator to define vehicle specs, but read RCVD and Tune to Win first. Everything revolves around the tires. Tires are incredibly important.

- Design a reliable car (i.e. parts won?t break). As the team gains more experience year-over-year, design a better and better car.

- Manufacture and assemble your car.

- Run the car as much as you can to get testing data and driver training.

And of course, enjoy the ride! FSAE will teach you a lot about engineering, project management, and working with cross-functional team members.

Further Reading?

Interested in seeing what my ?typical? day is like, working in Silicon Valley?

Day in the Life of a Silicon Valley Engineer

In Silicon Valley, there are quite a few Product Design Engineers. We are mechanical engineers who design consumer?

medium.com

Also, check out my 5 monitor desk setup:

The Crazy Desk Setup of a Silicon Valley Engineer

Why do you need 5 monitors?!

medium.com

Or check out why I believe that job hunting right now, isn?t as bad as you?d think:

Job Hunting During The COVID-19 Pandemic & Market Correction

Not as Horrible as You Think

medium.com

Footnotes

[1]: Disclaimer/disclosure: I am in no way affiliated with Milliken or Carroll Smith. Reading their literature is merely a suggestion. I believe that both books offer great information on how to make fast racecars. I may make a commission if you use those links. RCVD and Tune to Win may also be available in university libraries.

[2]: Disclaimer: I am in no way affiliated with Optimum G. Use of OptimumKinetics is merely a suggestion, as some top performing teams use this software. My team (UC Berkeley Formula SAE Team) did not use this software, since we developed our own custom software.

[3]: Disclosure: I am in no way affiliated with Steam or Studio 397. Utilizing racing simulators is merely a suggestion.