Many people are shocked by the look of Tesla?s Cybertruck unveiled two days ago on November 21st, 2019. However what few articles or commentators are talking about is exactly why it looks so different.

Many people seem to think it is because Elon Musk just wanted to go crazy and make something looking different for the hell of it. Many people are rejecting the Truck despite its impressive performance characteristics and utility simply because they don?t like the look.

A profound flaw in their thinking is that they assume the crazy look is a kind of unnecessary luxury or indulgence, and that a traditional look would have given it more utility.

However if you actually start to analyze this truck, you realize that the shape is a product of its function. Tesla did not start with: ?lets make a truck that looks this crazy and then added features.?

The features and characteristics of the Cybertruck dictated its shape. Form follows function.

The Design Goals that Dictated the Shape of the Cybertruck

Elon Musk has never been satisfied with just making another car or truck which is as good as existing fossil fuel variants, no his goal has always been to make the battery version superior. Otherwise how can you sell electric cars to a public that for a long time thought electric cars were equal to weak and silly little golf course buggies.

Thus when creating a truck, Tesla had to beat everything else that was out there:

- It had to be able to pull more load than any other truck.

- They had to offer more interior and storage space than the competition.

- They needed long range to be taken serious.

- It had to be rugged and be able to take a strong beating, if it was to be taken serious as a work vehicle.

- It had to be affordable.

Material and Design Choices Required to Meet Goals

To pull a heavy load the limiting factor is in fact not the engine itself. The electric motor easily gives enough torque to get the job done. The problem is the frame of the truck itself which will twist and damage under too much load.

In other words having superior capacity in tugging heavy loads requires a superior frame. You need a rigid and strong frame.

That suggests having a body-on-frame design, rather than a unibody design. What is the difference and why?

Difference Between Body-on-Frame and Unibody Design

Let us explain a bit of the terminology. The Frame is the bottom parts onto which to attach the frame and body. The body is typically the painted exterior you see.

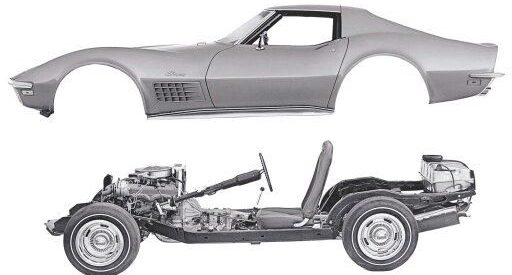

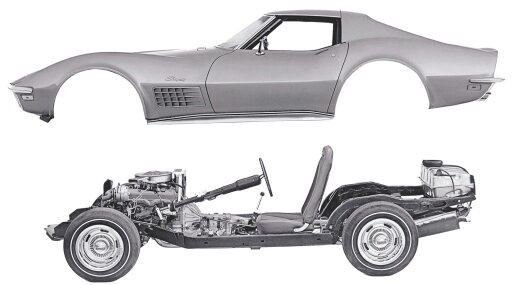

Body-on-frame design. The body is placed on top of a chassis.

Body-on-frame design. The body is placed on top of a chassis.

In a body-on-frame design, the frame and body are separate. In a unibody design they are merged. Body-on-frame is the old way cars were made. The strength and the structure was in the frame. Eventually unibody design were developed where the strength was actually in the combined body and frame. This reduced weight, improved fuel efficiency and improved collision safety.

Unibody design. The body and frame is made into one piece. They are not seprate.

Unibody design. The body and frame is made into one piece. They are not seprate.

Yet trucks and off-road vehicles typically don?t have unibody design despite its advantages. Why? Because using a separate frame usually makes the vehicle stronger with respect to twists, which matter when going off-roading and hauling heavy loads. It also makes it easier and cheaper to repair a vehicle which matters when the vehicle often takes a heavy beating.

Why Tesla went for Unibody Design

Despite all this, Tesla went for a unibody design. This has to be understood in relation to other design goals. They wanted a spacious vehicle, they needed space for batteries and they needed to keep weight down as is a challenge for all electric cars. With body-on-frame design you loose a lot of space at the bottom, where the frame is. This is exactly where you want to be able to place the batteries.

So how do you overcome the problem of twisting with a unibody design? You go for really strong materials like hard 30X cold-rolled stainless-steel as the Cybertruck uses. This has many benefits. It makes the car rust resistance unlike the mild steel normally used in cars. It makes it much tougher on the outside, which mitigates the need for frequent cheap repairs which typically favors a body-on-frame design.

Why the Triangular Look?

In construction triangles are known as one of the strongest geometric shapes in addition to archs. The triangles give the truck a lot of strength. Remember the body itself has to give the truck strength given that there is no frame underneath the body.

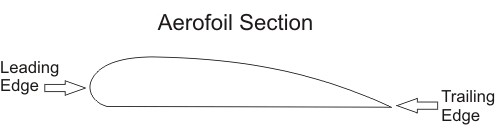

A second reason is aerodynamics. The overall trianglular shape of the Cybertruck follows the shape of an Aerofoil cross section much more closely than a traditional truck. This gives less air resistance and is important for any electric vehicle aiming for long range.

Consequences of cold-rolled stainless-steel choice

However this choice affects a lot of the rest of the truck. There are good reasons few cars are made in stainless steel. The last car which did that was the DeLorean, the car famously seen in the back to the future movies.

Last famous car made in stainless steel, the DeLorean made famous in the ?Back to the Future? movies.

Last famous car made in stainless steel, the DeLorean made famous in the ?Back to the Future? movies.

Stainless-steel is hard to paint and hard to shape. That is why the smooth curves you normally see on modern cars is entirely missing from the Cybertruck cannot easily be done using stainless steel. DeLorean actually kind of cheated by using a thin sheet of stainless steel, which is not what the Cybertruck is doing.

Elon Musk explains why the Cybertruck cannot have the soft curves of ?normal? cares. The steel alloy used is simply to hard to shape that way.

To get an idea of just how strong the steel alloy used in the Cybertruck is, consider this tweet by Elon Musk:

Because it is unibody and needs strength to pull, the Cybertruck can e.g. not have an L-shaped bed in the back as most trucks. Due to the stainless steel it cannot have smooth curves. That is why you see tough military vehicles with thick steel plates have rigid lines.

With these design constraints Tesla had to make some hard choices about the exterior design. They could not make it look like anything they wanted. They could have made it look like something like the Humvee/Hummer or some other military vehicle.

Notice how the hummer has a lot of the same kind of angled and straight lined look as the Cybertruck. Would people have preferred this look? I don?t think so.

Notice how the hummer has a lot of the same kind of angled and straight lined look as the Cybertruck. Would people have preferred this look? I don?t think so.

Instead they opted to make it look like a futuristic military vehicle. I personally think that was a smart choice. If you made a military look it would only have appealed to people who like military look.

With this design they can appeal to both military guys as well as tech fans who frequently love science fiction. A lot of the Tesla followers are also fans of space exploration through Elon Musk?s other venture, SpaceX. Here was an opportunity to create a tie in with things like Mars rovers.

Where Tesla went wrong

I think the problem is Tesla isn?t really telling this story. Hence people think Elon Musk went for the Mars rover look simply because he thought it was cool. For gruff guys who want a workhorse that just does the job, is suspect that is a turnoff. Any suggestion that form is selected over function is a turnoff for them.

What Tesla needs to make clear is that in fact all those features people love about the Cybertruck, such as lots of interior space, pulling heavy loads and low price is directly connected to its unconventional look.

By using steel rather than aluminum as electric cars normally do, you reduce price. By using unibody you reduce weight and increase range. You also increase interior space.

The Solar Advantage

Another advantage which is not mentioned frequently is that the large flat angled area on the back of the truck is an excellent opportunity for a large solar panel. In fact Elon Musk confirms in a tweet that solar panels will be an option.

For a normal car there would be no obvious place to place such a large solar panel. With this design the truck can charge enough electricity for a 24 km (15 mile) drive each day. The average American drives 46 km (30 miles) per day. Hence you get half your drive charged on solar panels. That is pretty good.

The Cybertruck looks weird because it has to, given its design constraints. A unibody design of hard stainless steel does not allow you to make something that looks like a regular truck. Unibody stainless steel is needed to compensate for the extra weight and space required for batteries. It is also a way to give the truck advantages over other trucks such as superior load pulling, tough exterior and superior internal space.

Some holdouts are like ?When Tesla sees the reaction they will probably modify the design and make a more traditional looking mass market version.?

People saying that simply don?t understand why it looks the way it does. They think it is a purely esthetic choice. The problem is that if Tesla should go back on their design and create another version it simply could not have the features and advantages of the Cybertruck. In this case, form follows function.