Who Builds Robots Series

That?s me using my favorite Dremel. You wouldn?t believe how many tools I use on any given day.

That?s me using my favorite Dremel. You wouldn?t believe how many tools I use on any given day.

?Mech-a-what?? ?What?s a mech-aaaa-TRON-ic engineer?? ?What?s mechatronics?? ?So, you?re a mechanical engineer??

Welcome to one of the first sentences I typically hear after introducing myself as a mechatronic (mech-a-tron-ic) engineer. Recently at a networking event in Oakland, California, I was asked ?Did I hear you right in saying you?re a mechatronic engineer? I?m a recruiter, and I?ve seen that term a few times from applicants, but I don?t actually know what that is. Could you explain it to me??

Sure ? read on!

Mechatronic engineering is an engineering ?specialty? that?s been around for quite some time, but wasn?t assigned its own field classification until recently. To put it simply, mechatronic engineering is a hybrid of mechanical, electrical, and computer engineering. This puts applications of robotics, control systems, electro-mechanical systems, and similar engineering in this field.

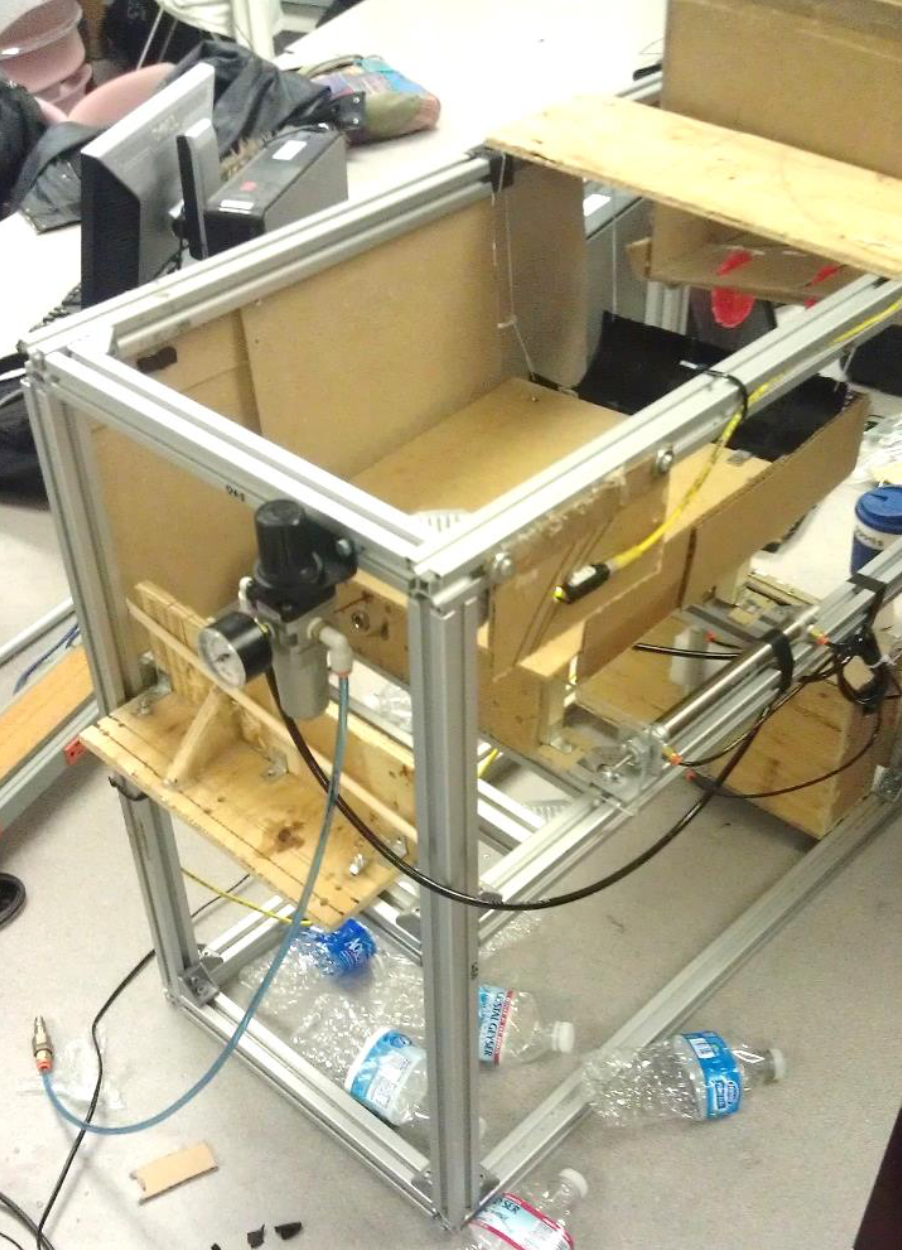

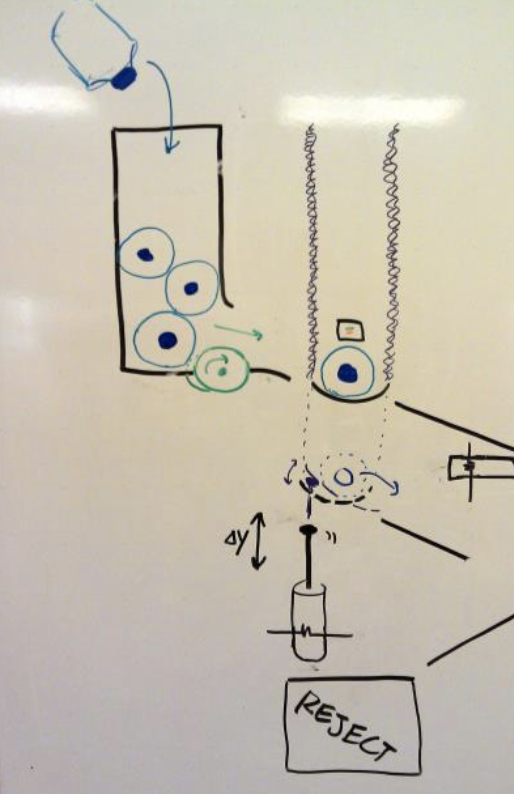

A water bottle crusher I created for my Intro to Engineering & Design class ? you don?t have to be a perfect artist to make good designs.

A water bottle crusher I created for my Intro to Engineering & Design class ? you don?t have to be a perfect artist to make good designs.

A great way to illustrate this is to think of us as go-betweens for mechanical and electrical teams, being able to speak both languages of the different fields, while not necessarily being specialized in one field over another (though having strengths in one versus another is likely). Some ?mechas,? as we may refer to ourselves, have additional backgrounds in computer science, computer engineering, manufacturing, electrical engineering, or business.

So why has no one actually heard of us? My guess is it?s due to schooling ? most know of mechanical, electrical, computer, civil, aerospace, robotics, and other degrees, partly because they?re offered at schools all over the world. Not very many schools offer a dedicated mechatronic engineering degree, though, which severely limits the exposure of this recently defined field.

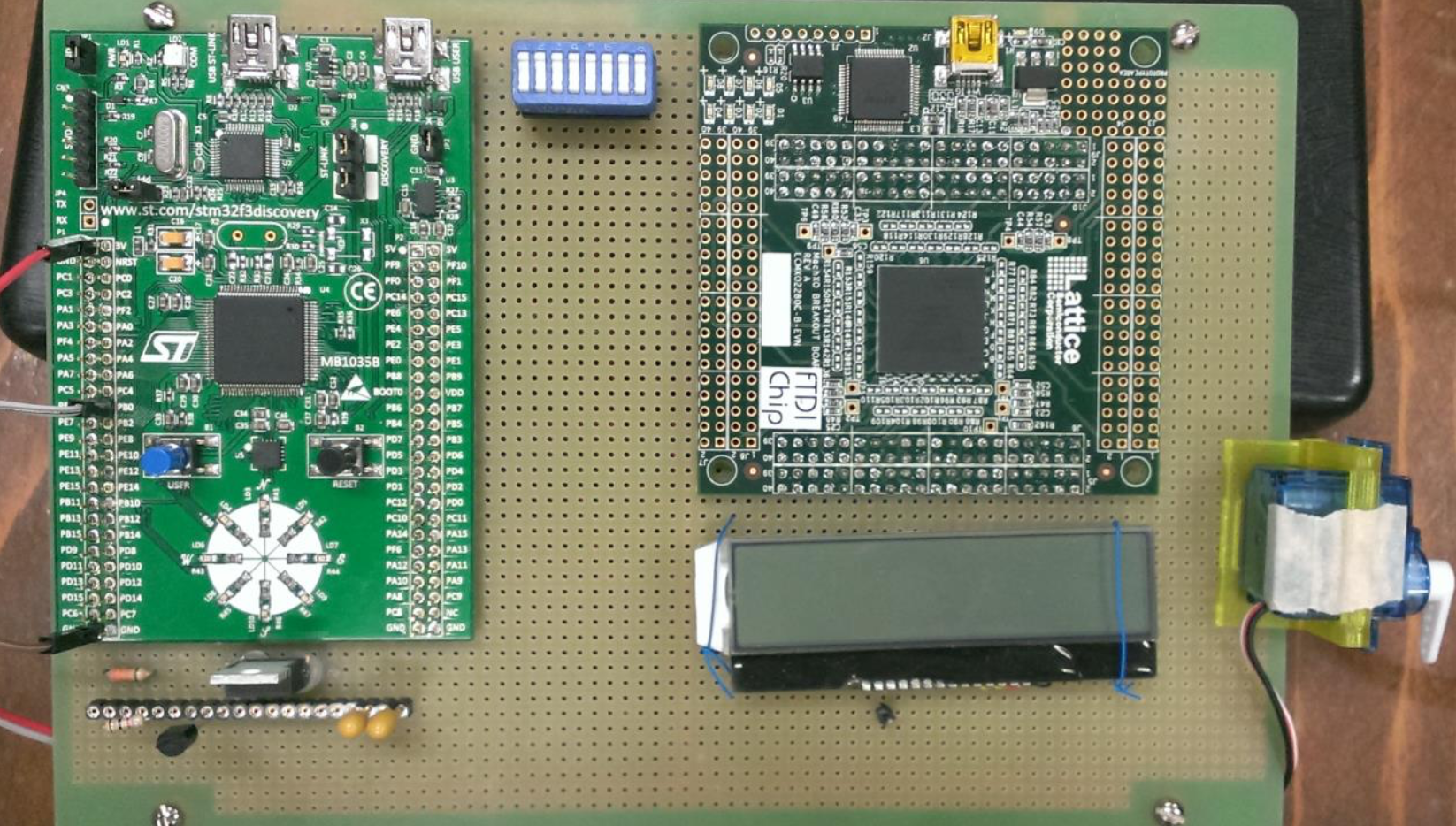

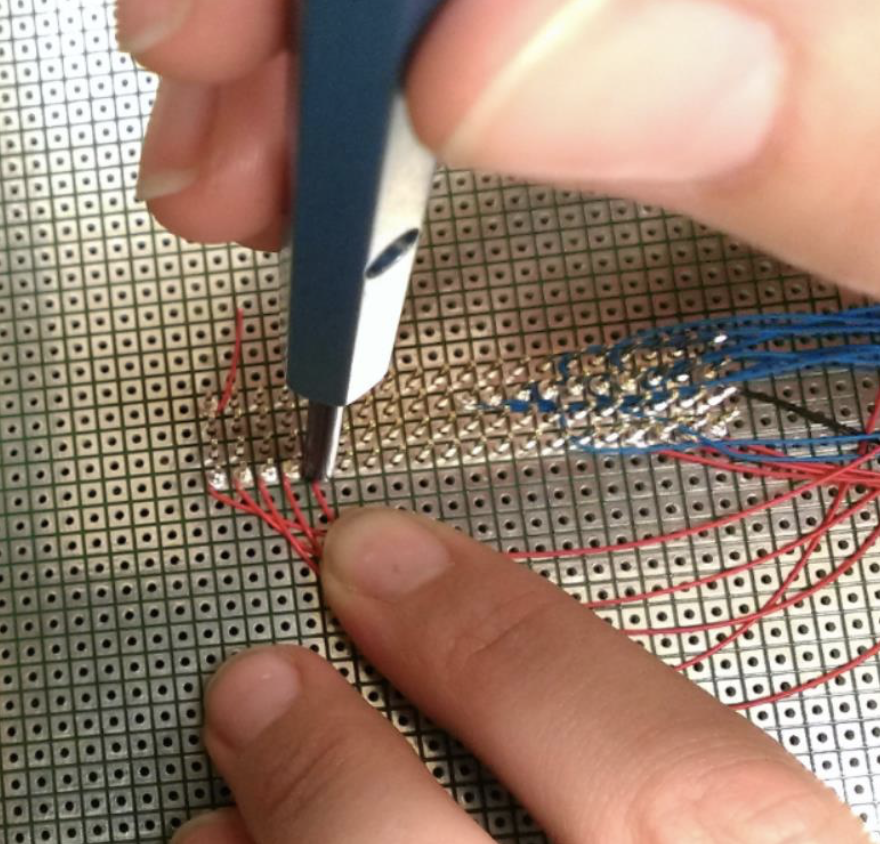

On the left, a digital safe project I made for my Embedded Systems Design class. On the right, I?m wire-wrapping components to the printed circuit board.

On the left, a digital safe project I made for my Embedded Systems Design class. On the right, I?m wire-wrapping components to the printed circuit board.

On top of that, many consider ABET-accredited programs to be of the utmost importance, including the ability to get engineering-based scholarships at the university level. But as of October 2017, there are only eight 4-year colleges offering an ABET-accredited mechatronic engineering degree in the U.S.:

- California State University, Chico (year of accreditation: 1996)

- Central Connecticut State University (2015)

- Kennesaw State University (2011)

- North Carolina State University at Raleigh (2009)

- Purdue University Northwest (2011)

- University of Detroit Mercy (2015)

- University of North Carolina at Asheville (2009)

- Vaughn College of Aeronautics and Technology (2011)

CSU Chico was the first in the country, earning accreditation in 1996, and it was the only one to hold that distinction for the next 13 years. It?s where I earned my own mechatronic engineering degree.

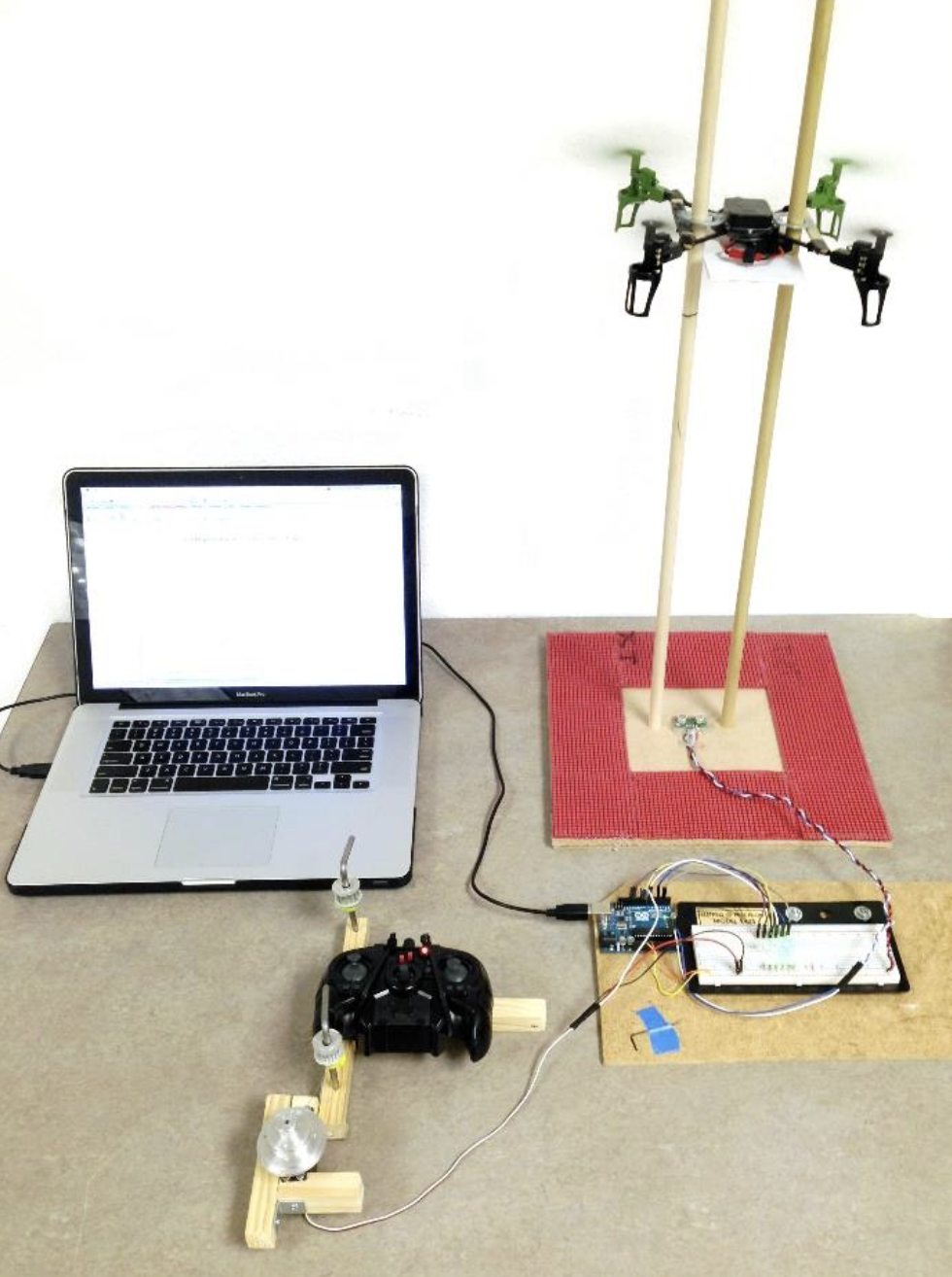

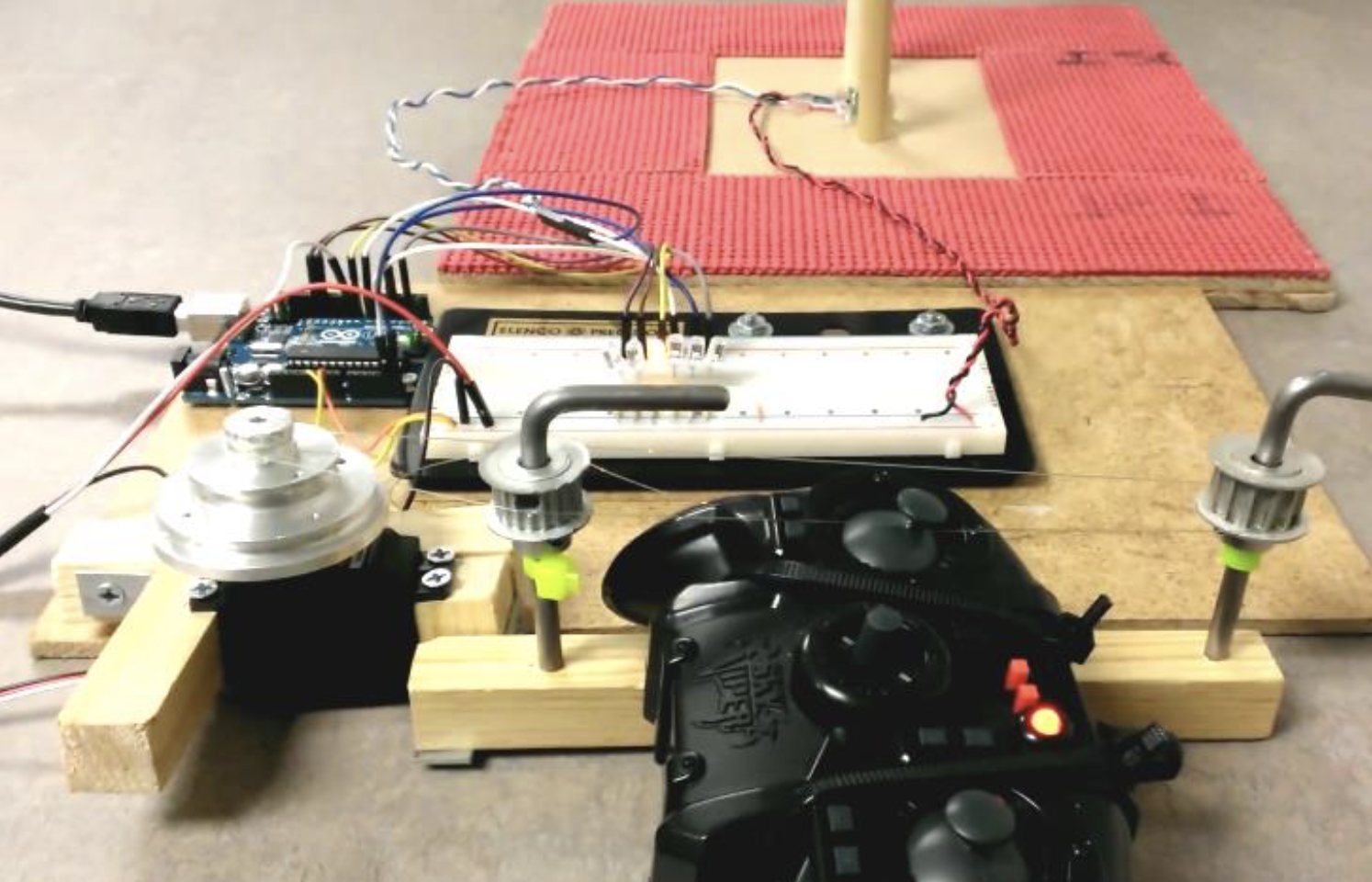

For a Control System Design class, a group of us made a PID (Proportional-Integegral-Derivative) system to control a quadcopter.

For a Control System Design class, a group of us made a PID (Proportional-Integegral-Derivative) system to control a quadcopter.

So ? why am I a mechatronic engineer, and how did I end up here?

When I was in high school, I considered going into architecture and took courses to learn 2D and 3D AutoCAD and Autodesk Revit skills. During my sophomore year, I worked part-time at a local backpack & messenger bag factory doing 2D CAD work for them, and started taking engineering classes during summers and at night, where I picked up mechanical drafting and SolidWorks experience. These opportunities, topped with an experience of being bored with architecture a year or two later, told me design and engineering were more my style, so I began to look at college options.

My mom and I heard that California State University, Chico had a good engineering program, so we checked out the catalog. It was here that we first heard about mechatronic engineering. The description reminded me of a book I loved that my aunt had gifted me many years prior ? ?The New Way Things Work? by David Macaulay ? that goes into whimsical detail about everyday things such as inkjet printers. The program description for mechatronic engineering listed tech such as anti-lock brakes, robotics, and inkjet printers as applications for such a degree, so I decided ?Why not?? and went for it. A few years later, I had two degrees. While still in high school, I got an associate?s degree in Drafting and CAD Technologies from my local community college. Then I earned my Bachelor?s of Science in Mechatronic Engineering from Chico State, with minors in manufacturing and computer engineering.

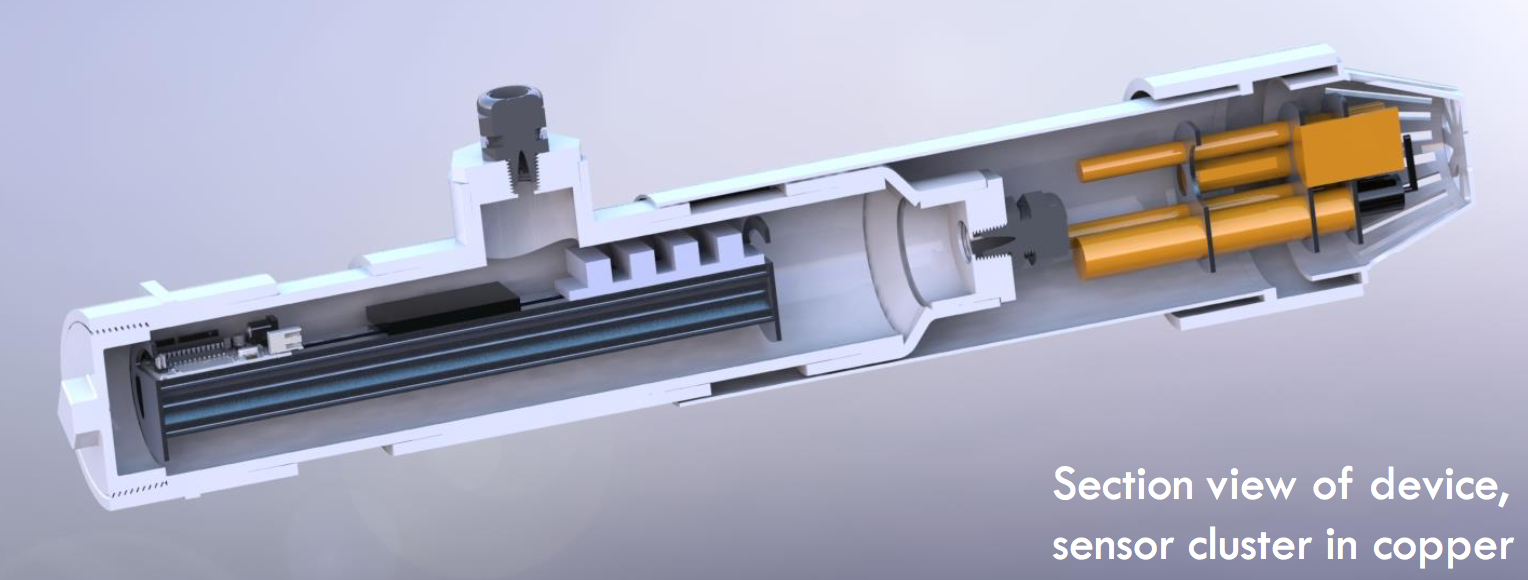

For our senior Capstone Design project, a group of us made a water quality sensor that was designed to log data while being submerged for up to a month.

For our senior Capstone Design project, a group of us made a water quality sensor that was designed to log data while being submerged for up to a month.

During my university years, I took courses that covered topics such as embedded systems, electronics, programing in C/C++, mechanics, physics, calculus, statics, strengths of materials, manufacturing processes (learned to weld steel and cast liquid aluminum there!), program PLCs, size motors and bearings, linear circuits, material science, and many more.

After all that intensive studying, once I graduated, did I know what I wanted to do right out of the gate? Nope.

I did know that I wanted to get my hands on robots or be involved with sensor-based technologies and wearables such as smart watches. (Interestingly, I wasn?t involved in FIRST Robotics during high school. I?d not even heard of FIRST until I applied for college scholarships. I ended up mentoring a brand-new FRC team for a few years during college, so I wasn?t totally deprived of the experience.)

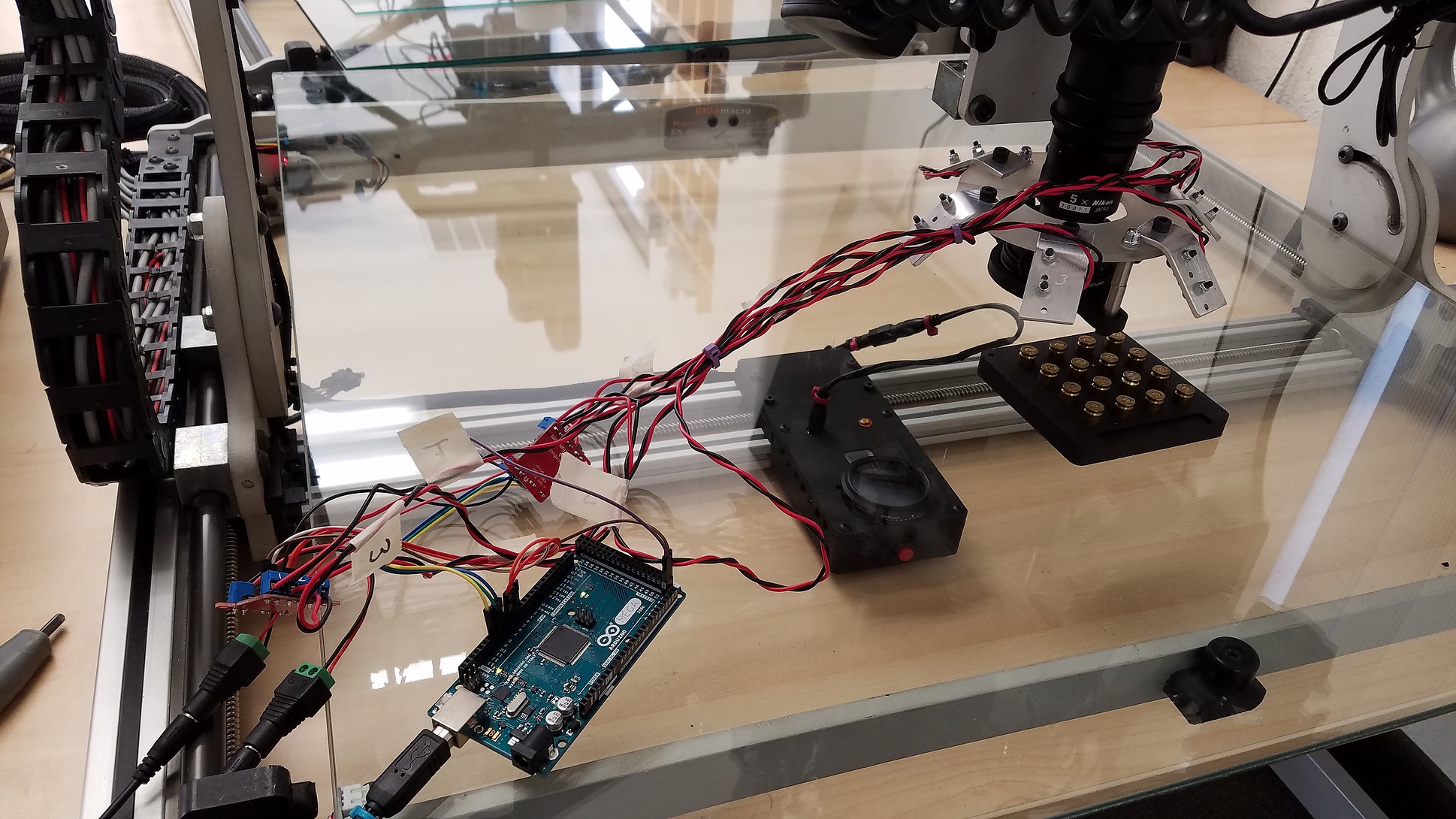

After graduation, I joined a small company in Napa, California, doing some fascinating robotic photography systems. Here, I wore many hats. I prototyped new concepts for machine add-ons, I manufactured parts from thick slabs of plastic, built the machines, built the shipping crates, made the wire harnesses, programmed control boards, and more.

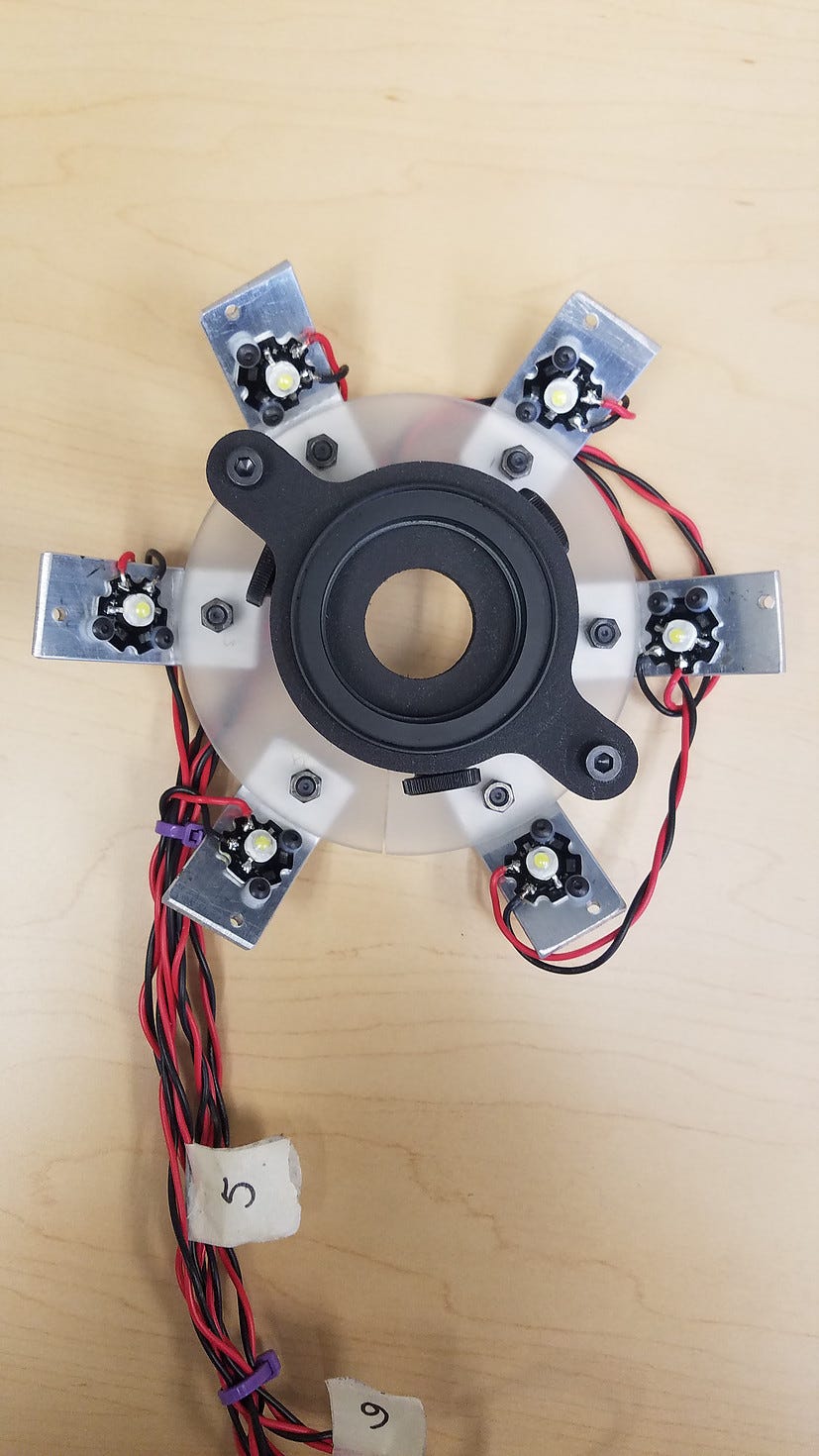

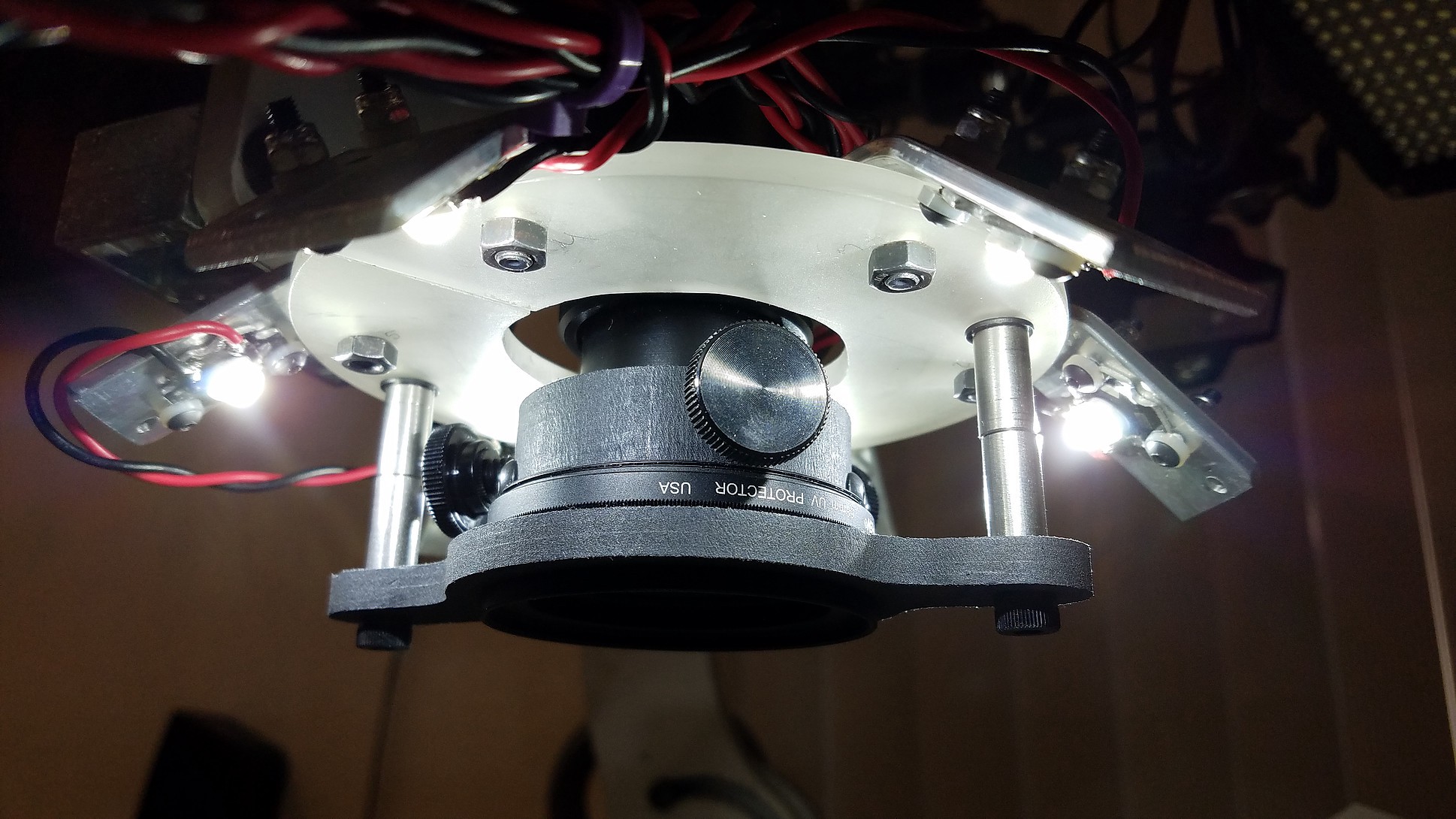

A 3-watt, 6-LED array prototype I made for use with an imaging system.

A 3-watt, 6-LED array prototype I made for use with an imaging system.

After two years here, it was time to move on. Silicon Valley was bustling with opportunities, but none were the right fit for me, so I decided to broaden my horizons. Fast-forward a few months, and I accepted a role to make super-cool robots for the home. I fell in love with the robots I saw in the office and knew right away that I wanted to be a part of this; I packed up my life and moved to Colorado to make it happen.

The tools I?ve used in my work in general cover a pretty wide gamut:

- SolidWorks

- DraftSight?

- AutoCAD

- Autodesk Fusion 360?

- Arduino?

- Raspberry Pi

- Dremel tools

- digital multimeter

- soldering iron

- drill press and other standard shop tools and hand tools

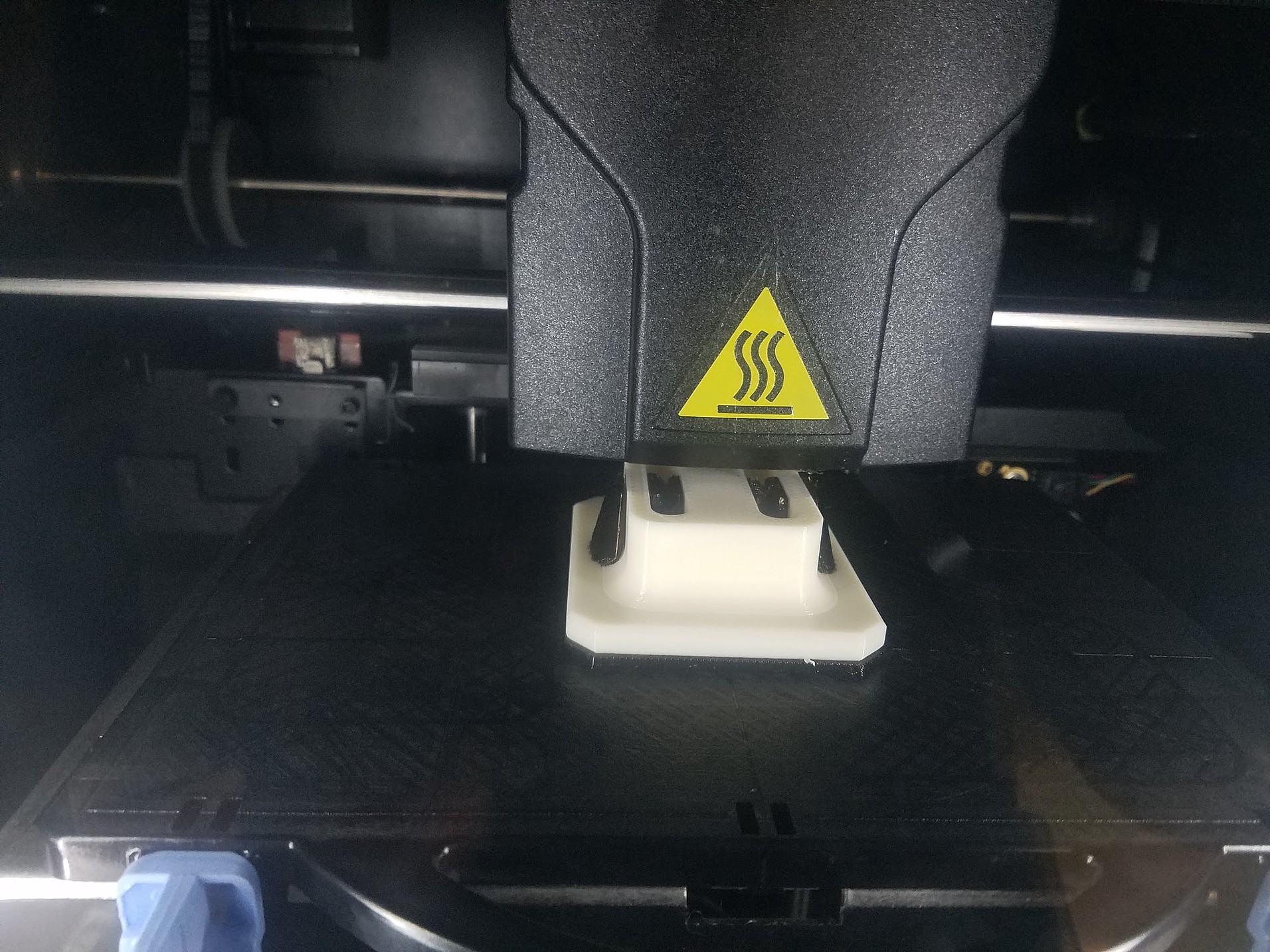

- 3D printers (we run MakerBot printers at the office)

- 90W 48″x36″ laser cutter

- vinyl cutter

- ?and my trusty pocket knife!

A personal project designing and printing a phone mount for my car.

A personal project designing and printing a phone mount for my car.

So in a nutshell, we?re a jack-of-all-trades-master-of-none sort. We?re specialized at not being specialized, yet mechatronic engineers can do quite a bit across multiple engineering disciplines and have a solid base from which to grow.

Mechatronic engineering alumni work with massive industrial robots, smaller robots in pick-and-place operations, control systems for bottling or packaging of food and drink products, drones, designing control systems for rides in amusement parks, prototype development, or even working to bring a robot to every home and office such as myself.

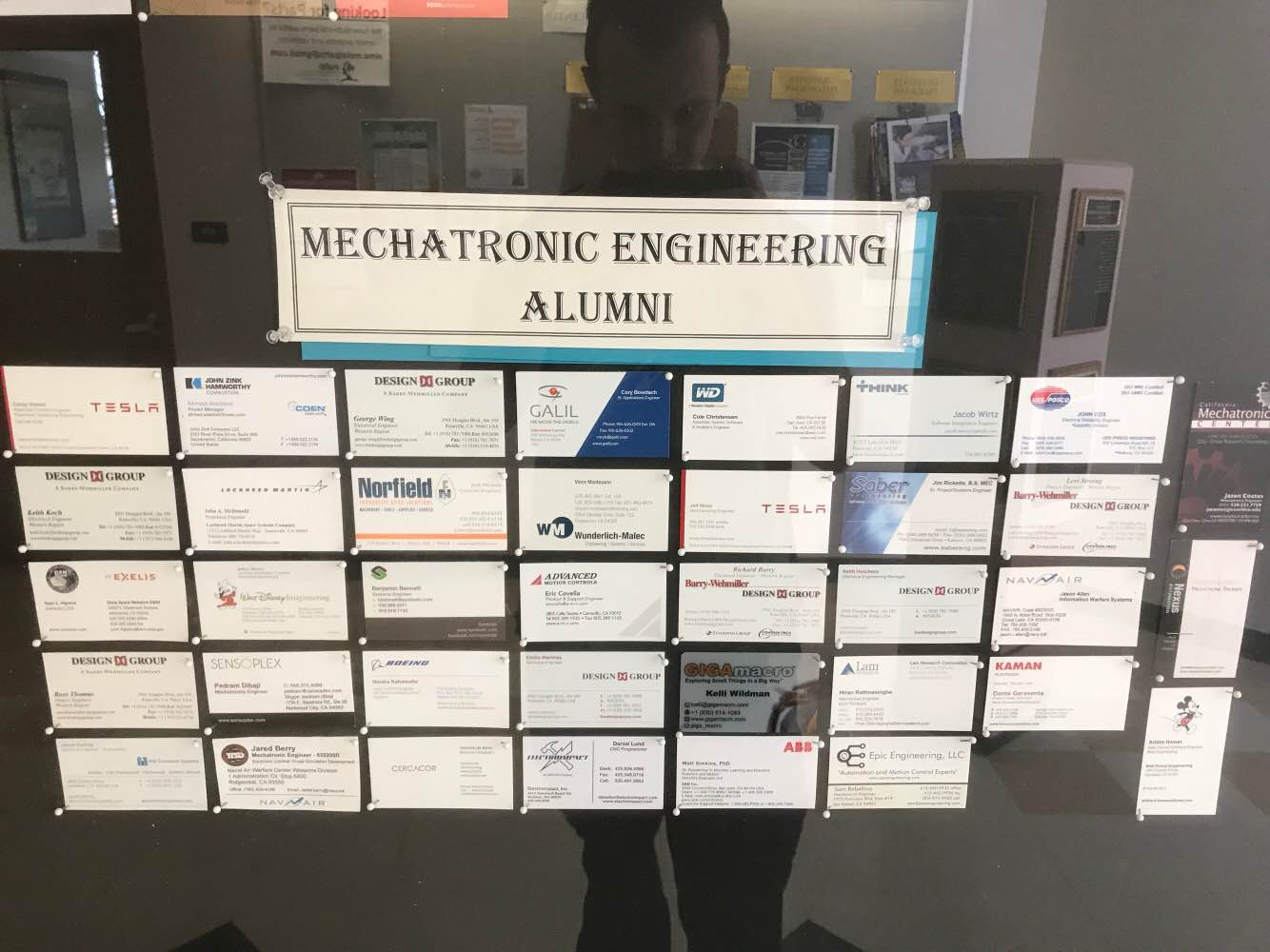

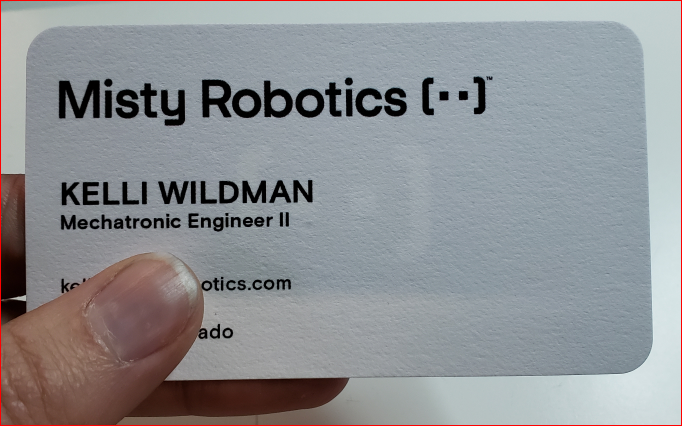

On the left, business cards from CSU Chico alumni ? the see-through one roughly in the middle is my old business card. On the right, my new card.

On the left, business cards from CSU Chico alumni ? the see-through one roughly in the middle is my old business card. On the right, my new card.