In the world of fluid power application, the difference between hydraulics and pneumatics are often comprehensively covered.

These two kinds of power circuits are actually similar in a number of ways in that they both use a fluid to channel mechanical energy as well as in the executions, terminology, and components.

Both systems likewise require a certain type of pump and some valves for force and velocity control of the actuators.

However, the differences between the two spell out how and where each one can be most useful in relation to your needs.

Significant Differences

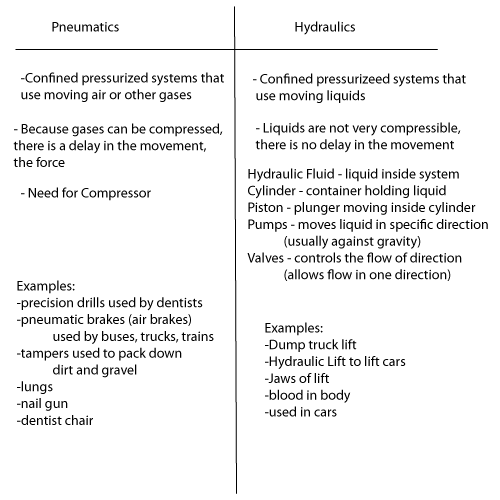

The difference between pneumatics and hydraulics actually lies in the medium that is utilised to transmit power. Pneumatics use easily-compressible gas like air or pure gas. Meanwhile, hydraulics utilize relatively-incompressible liquid media like mineral oil, ethylene glycol, water, synthetic types, or high temperature fire-resistant fluids to make power transmission possible.

Because of this primary difference, some other aspects about these two power circuits also follow suit. Industrial applications of pneumatics utilise pressures ranging from 80?100 pounds per square-inch, while hydraulics use 1,000?5,000 psi or more than 10,000 psi for specialised applications.

Moreover, a tank would be needed in order to store the oil by which the hydraulic system can draw from in cases of a deficit. In a pneumatic system however, air can simply be drawn from the atmosphere then purified via a filter.

In a nutshell, their differences are as follows:

Optimising Strengths

You can count on pneumatic systems to have simplicity of design and low initial costs. This is because air-operated circuits operate at comparatively low pressure and components can be made from inexpensive material that cut secondary machining costs and operations.

On the other hand, this is not something that you cannot expect from hydraulic circuits initially because it requires a power unit that should be part of your machine. And so, if you want to start out in a less expensive manner, air circuits could be the right choice for you.

In the meantime, cost scenarios are going to be different in the long run. Pneumatic circuits could be 5?10 times more expensive in terms of operating costs.

Apparently, tons of horsepower is required to compress atmospheric air into its normal working pressure. This makes air motor components very costly to operate. As for hydraulics, the high initial cost can be often offset by low operating cost with its higher efficiency. Hydraulic-powered machines operate at higher pressures from 1500?2500 psi and thus generate higher force from small-scale actuators.

When a certain manufacturing plant has several hydraulic machines, it is ideal to set up central power units to benefit from its advantages. Machine noise levels are going to be substantially reduced, uptime for all machines increased, and back up pumps will be available in case a working pump breaks down.

In terms of housekeeping, pneumatic systems are easier to maintain in comparison to their hydraulic counterparts. Air-operated circuits are cleaner as its force transmitter is atmospheric air. Any leaks will not cause problems.

However, this can be quite expensive and it will take about five compressor horsepower to provide air to a typical handheld blow-off nozzle then maintain 100 psi.

Thus, even if hydraulics housekeeping can be a problem, proper measures just needs to be employed to remedy the issue. Appropriate plumbing procedures, preventive maintenance, and the right materials can help minimise hydraulic leaks.

Best Uses for Hydraulics and Pneumatics

Pneumatics

Pneumatics are typically used in factory set ups, construction, mills, building, and technology by using a central source of compressed-air for power. Medical applications of pneumatics are likewise common including the high-powered drill of a dentist. Practically everything could run on pneumatics including any form of transportation. That little tube in a bank?s drive-teller operates through pneumatics via a high pressure source of compressed air.

Hydraulics

Hydraulics have varied uses in everyday life and most of them are applicable to machines. For instance, hydraulics are applied in a car?s braking system. They only require a small force as the driver steps on the car brakes but a greater force is already produced to stop or slow down a car as it equally acts on all of the 4 brake pads.

Hydraulic applications are also evident in lifting equipment such as wheelchair lifts, excavating arms on machineries like diggers, hydraulic presses for forging metal parts, and wing flaps on aircrafts. Obvious uses of hydraulics are with heavy equipment.

Here at Worlifts, we have experience in the supply and maintenance in many industries such as Oil & Gas, Engineering, Rail and Renewables.