There are different mix ratios of Concrete. Mix ratios are decided based upon the type of construction structures and mix designs.

For Concrete Mix Ratio the components are ? Cement, Sand, Course Aggregates and Water.

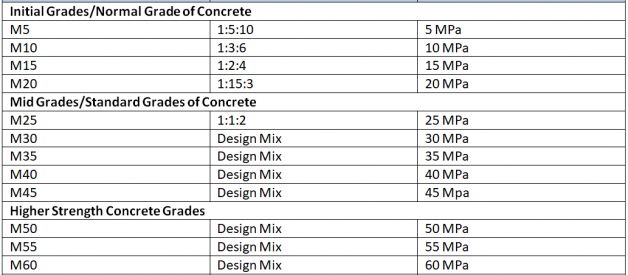

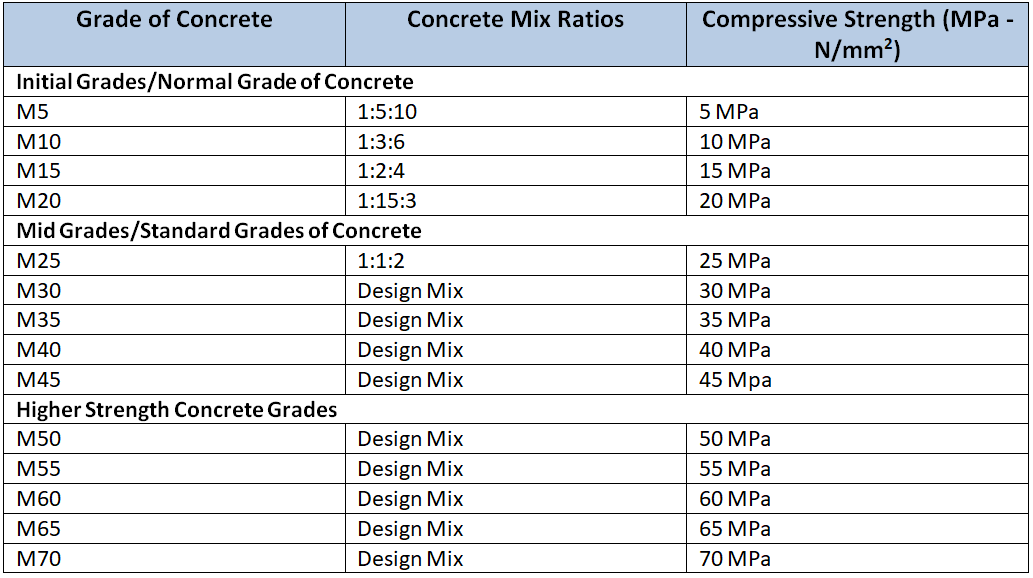

Different Grades of Concrete denotes its strength for required construction. The ?M? denotes mix. For example if the concrete mix is of M20 Grade then the compressive strength will be 20 MPa.

- Nominal Concrete Mix Ratios

Previously the specification for concrete was proportion of Cement, Sand and Course Aggregates. The fixed ratio of these was to ensure the strength to the structure.

- Standard Concrete Mix/Ratio

As per Indian Standards (IS 456?2000) concrete mixes are segregated into different grades. It starts from M5 and goes up to M40. M refers to Mix and the numbers are to signify the strength of Mix N/mm2.

The material proportion for each Grade is different.

M10 = 1:3:6

M15 = 1:2:4

M20 = 1:1.5:3

M25 = 1:1:2

- Designed Concrete Mix/Ratio

The proportion of the material is determined by the concrete mix expert in this method. In design mix the concrete production is with appropriate properties. In Design mix there is no guide for right mix proportions it follows the economical method as per the requirement.

It is followed by standard mixes ? quantities of dry materials per cubic meter and by plunge. This method is may use for small construction purpose where the strength is required on 28 day strength 30 N/mm2. Testing for this grade is not necessary the mix is placed on the bulk ingredients.

Here is the list of different types of concrete mix ratios and their strengths. For Mix proportions

First one = Cement

Second one = Sand

Third one = Coarse Aggregate

Based on the weight of materials the strength is measured with concrete cube by civil engineers.

The concrete cube/cylinders are made during casting for 28 days. After the hardening of the cube it is always recommended to perform the strength check. For reinforcement concrete construction minimum grade is M20 are used.