At Bra Theory, the price of your first custom-made bra is $350. Subsequent bras cost $250 per bra.

Reactions vary to this price point. You might be asking if a $350 custom-made bra is made of gold, or if it does the laundry. Or maybe you?re saying, ?anything for a bra that fits!?

If you?re used to the $60 price point bras you find off-the-rack, it?s hard to make the leap from $60 to $350. At any rate, wherever you stand, it helps to understand what you get from a custom-made bra.

Here?s the breakdown of what it costs, and more importantly, what value you?re receiving.

1. Measuring ? 20 minutes

After the measuring process for a Bra Theory custom-made bra, a customer remarked, ?It takes more than 15 seconds and a pink measuring tape to tell your size.?

In the process for a bespoke suit, a tailor will take anywhere between 14?24 measurements.

It only makes sense that a custom-made bra will take many more measurements than the standard two that you get in the fitting room.

With custom-made, a fitter will spend 20 minutes measuring you carefully, with more precision than is customary in the store. The Bra Theory process is in beta, but as of September 2018, it includes 21 points of measure.

It takes more than 15 seconds in a fitting room, with two loops over a bulky sweater, to give you a precise size.

It takes more than 15 seconds in a fitting room, with two loops over a bulky sweater, to give you a precise size.

2. A conversation about what YOU want ? 20 minutes

With shopping off-the-rack, often, what you see is what you get. With custom, you get a voice in what you want to see.

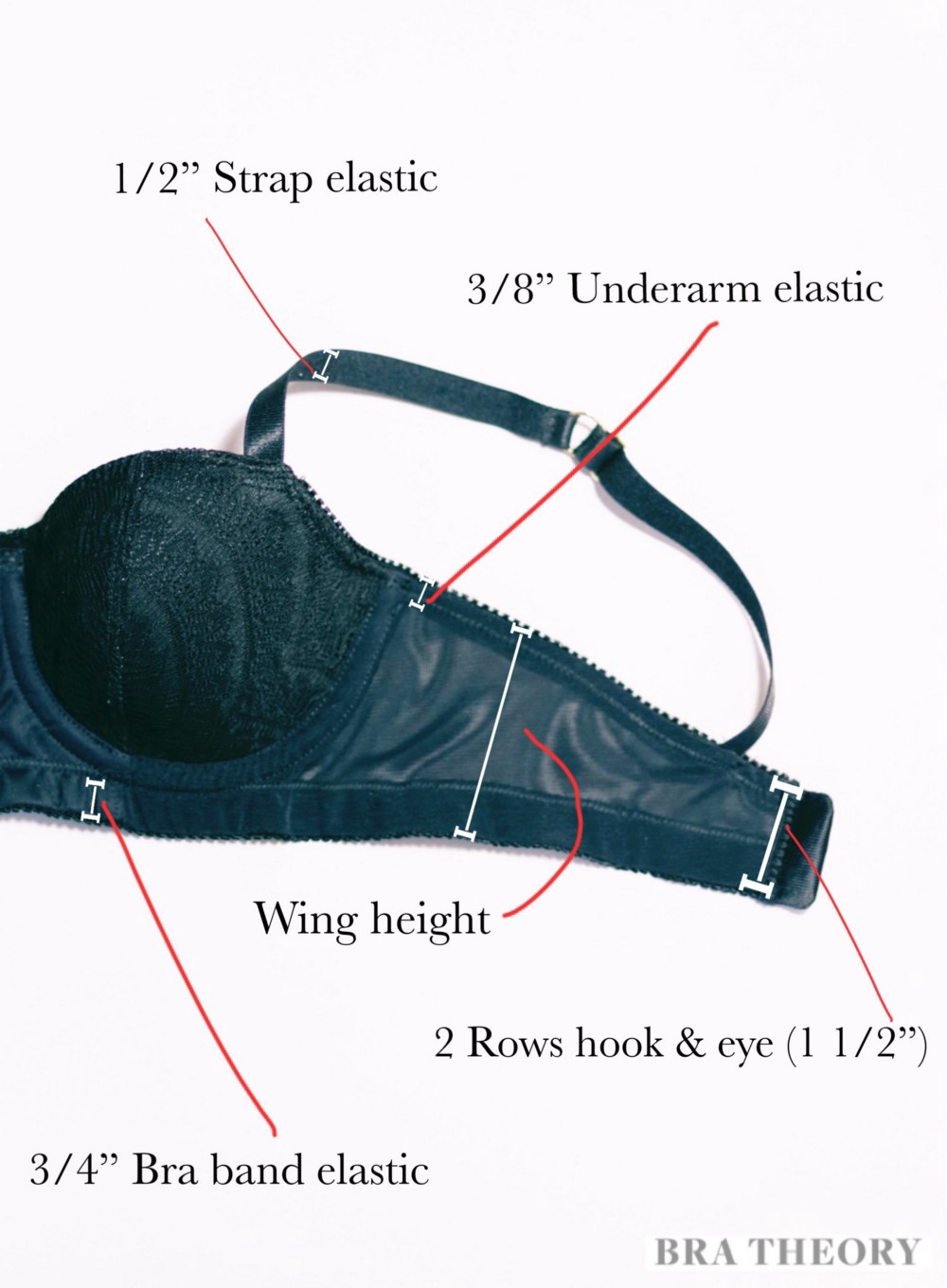

For example, some customers express concerns with the ?caterpillar? look of bands that are too tight, and our fitters will recommend a wider band with 3 or 4 rows of hooks and eyes. Others will express a strong preference for support, which means that we might recommend a 1″ wide strap instead of 3/8″.

Of course, while anything is possible, there are trade-offs: for example, a 1″ wide strap will not work with every outfit, and will look thick on the body.

The custom bra-makers are there to give you expert guidance on what?s possible with bra design and engineering, so that you can make an informed decision.

3. Pattern-making ? 1 hour

Once your measurements are taken, the first step is drafting a pattern made precisely for your body.

You can think of a pattern as the unique blueprint to your bra, drafted based on your measurements.

Blueprints in the making by our in-house bra-architects.

Blueprints in the making by our in-house bra-architects.

Pattern-making requires a deeply intuitive understanding of the translation between 2D and 3D. This is especially true for bras, since it is a rounded 3D shape.

Fun fact: it is mathematically impossible to make a perfect sphere from a flat sheet of paper. Modeling a rounded 3D shape in 2D requires mastery and intuition.

Fun fact: it is mathematically impossible to make a perfect sphere from a flat sheet of paper. Modeling a rounded 3D shape in 2D requires mastery and intuition.

It can be difficult to draft a pattern correctly on the first try, especially when you consider that different fabrications require different engineering. Even industry experts struggle with getting the pattern right on the first try ? we?ve heard as many as 19 fittings for tricky fits. And that?s only for their selected fit model.

?which leads us to the next step in a custom-made bra.

3. Fittings and alterations ? 30 minute fittings, 1 hour pattern revisions, rinse and repeat

It is unlikely that a custom-made bra will fit you on the first try. In fact, one pattern-maker with 25 years of industry experience shook her head and told us, ?When a bra fits on the first try, we consider it a gift.?

When a bra fits on the first try, we consider it a gift.

Small wonder that it?s a struggle to find a bra, when making one isn?t even fully understood!

In the custom process, once the initial pattern is drafted, a prototype bra is cut, sewn, and fitted to your body. The prototype is not made of the final fabrics or trimmings? it?s meant to check the fit.

Based on the fit notes, the pattern-maker will update your blueprint. Another prototype is cut and sewn, and the process repeats.

You get a sense of certainty with the prototyping process.

Each iteration improves the fit, and it can be shocking to see how we get there. You might be fitted with a bra that seems on par with your current bras, an ?okay? fit with a little bit of quadboob. Then, you?ll watch as our bra-makers slash and spread the cup to give it more room in the pattern.

Depending on the idiosyncrasies of your body, the fitting process can require 3?5 in-person fittings. If the style being tested is particularly complicated or in R&D, it could take up to 17!

If it takes more than the average number of fittings, it is important to remember that you are NOT weird, overly sensitive, or anything of the sort. Think of it this way: you are exceptional, you have good taste, and you know what you want.

Lingerie designers can spend as many as 10 prototypes, if not more, during the research and development process to perfect a new style. It can cost thousands of dollars and years to develop a lingerie line in one size, let alone a size range.

With ready-to-wear, the upfront costs of developing a size range are amortized over time. With custom-made, the upfront cost of developing the pattern is paid upfront on the first bra.

4. Hand-Sewing ? 1?2 hours for a prototype, 3?4 for a finished garment

Yaffit Salmanson, the founder of a premium luxury intimates company, Nooar, describes the cost for smaller-scale manufacturing: ?When you manufacture in a high volume production line, the setup time of the sewing machines ? which is translated to skilled labor work time ? is relatively negligible and isn?t a large component of the cost. However, for custom bras, or even for small-scale manufacturing, this cost isn?t spread out over thousands of units and therefore more significant.?

For custom-made bras, you can imagine that a highly skilled seamstress is giving your bra her full attention, start to finish. The bra naturally takes longer to sew when it is not one of many 34B?s to be assembled together.

Our production team in NYC.

Our production team in NYC.

Often, due to the level of customization, custom-made bras are produced locally, on fair and ethical wages. This can also add to the cost.

5. Materials ? $35 at the least

First, nice materials ? the ones that feel soft against the skin ? cost more.

?For a high quality bra, you?re looking at a material cost of 30 euros, or close to $35,? says Salmanson.

Secondly, an underwire bra is a highly technical garment with many components, including fabric, trimmings, rings, sliders, hooks and eyes, and underwires ? each with a specific function.

You can think of a bra as a bridge. If you want something long lasting that works, you want something with solid construction and engineering. A steel suspension bridge is not the same as a wooden bridge, like an underwire bra is not the same as a bralette.

While the components required for better engineering can add up, it?s all summing up to a better quality garment for you.

Conclusion

When you purchase a bra for $60, corners are getting cut ? which precisely is why it costs $60. It?s made for a standard size, and not likely to be a perfect fit. In fact, the costs are passed on to you in terms of time spent shopping and dissatisfaction with the product. At the end of the day, you get what you pay for.

In comparison, a custom-made bra can take 24 hours of specialized labor, material costs for what you know is a high quality bra, and overhead costs for a startup business.

That?s what you get for $350 ? and honestly? We think it?s a steal.

If you think so too, you can join the wait for the Bra Theory beta.

Would you pay $350 for a custom-made bra? What does a bra have to do to check all your boxes? Let us know in the comments below!

Bra Theory?s mission is to crack the code on how to make custom-bras affordable for more people. As one of our customers aptly put it: ?it?s not bra magic, it?s bra science.? As of 2018, our bra costs $350 instead of $1000.