Along with the answers to other important questions like where did marshmallows come from and how are they made?

Is your favorite way to eat a marshmallow sitting next to a campfire making smores? Maybe you enjoy the Easter season because it?s the only time of year that marshmallow Peeps can be found? Marshmallows have somehow permeated the entire food sector, topping everything from sweet potato casseroles to hot cocoa. To understand how this sweet treat rose in popularity, let?s go back to its roots (literally).

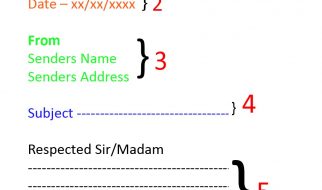

The fluffy candy is very appropriately named after the mallow plant, which is native to salty marshes in Asia and Europe. The combination of the plant name and the environment in which it grows led to the term marshmallow. The roots of the mallow plant can be squeezed to harvest a gooey sap. The sap is the only part of the plant that is incorporated into a marshmallow. It?s thought that the ancient Egyptians were the first to incorporate the mallow sap into a candy by mixing it with honey and nuts [1].

The French introduced the type of marshmallows we are more familiar with today. In the 1800s candy makers would whip together a mixture of mallow sap, egg whites, and sugar to produce an airy confection [1]. The whipping process allows air bubbles to be integrated into the candy syrup making it light and fluffy. The mixture was then poured into moulds to form desired shapes and sizes.

Throughout the years, the recipe for marshmallows has evolved to the point where we no longer use the sap of the mallow plant, although the original marshmallow name continues to be used. The rest of the recipe remains largely unchanged. You combine sucrose (table sugar) and corn syrup with enough water to dissolve the sugar. This sugar syrup is then heated to a certain temperature, typically between 220?240F, depending on how much water you want to boil off [2]. The amount of water impacts the final texture of the marshmallow. The hot syrup is removed from the heat source, slightly cooled, and a protein stabilizer like gelatin is added. Really you could use many different proteins here, including egg or milk proteins, but gelatin is the most widely used stabilizer in marshmallows. At this point, the marshmallow is only missing one ingredient ? air.

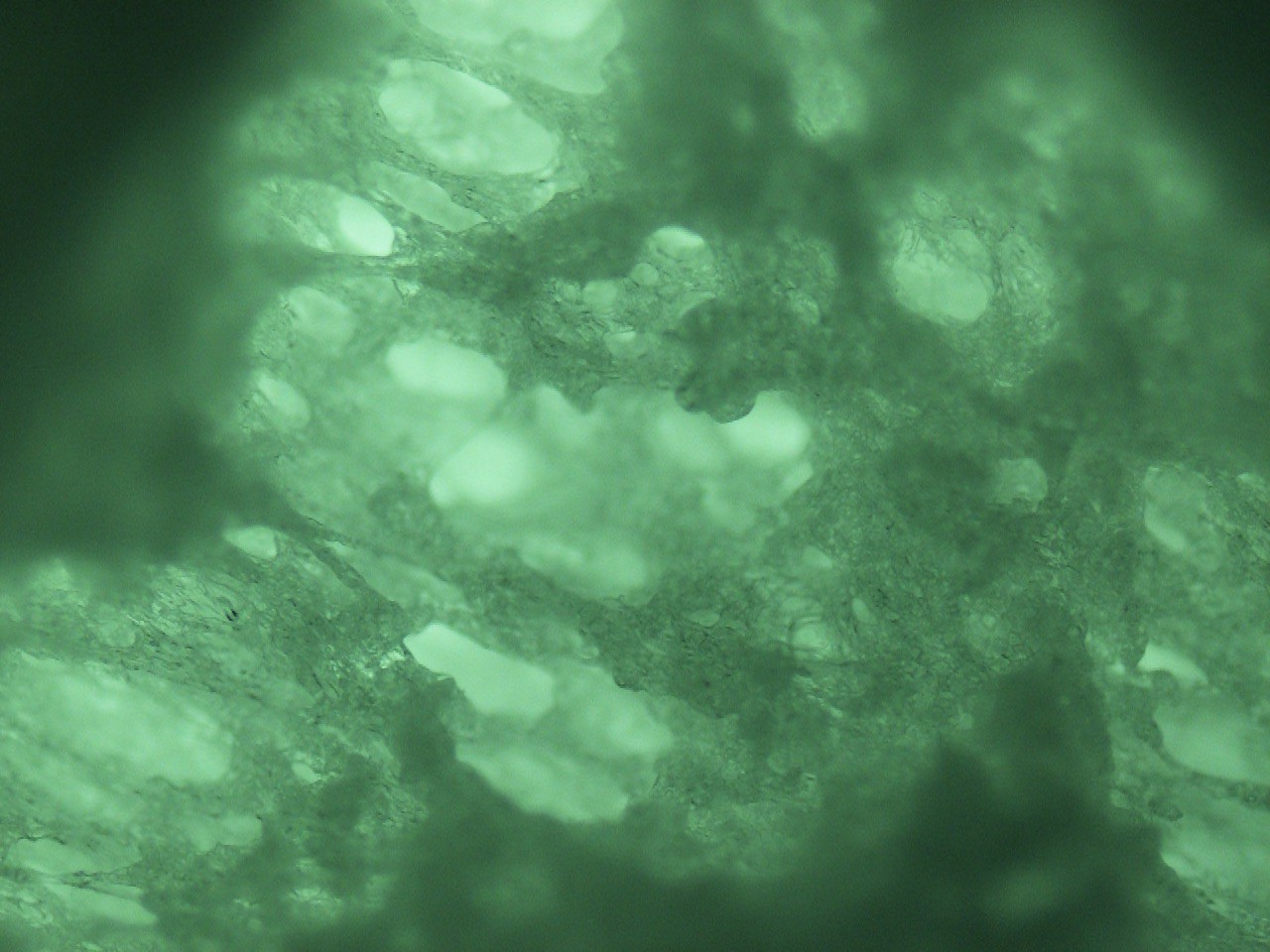

Aeration of this sugar-protein mixture is the key processing step in marshmallow production since marshmallows are over 50% air! That?s right, when you purchase marshmallows you are mostly paying for air. To introduce air into the mixture, typically a whisk or some type of beater is used. This is a simple process of whipping and pulling the mixture so that small air bubbles become incorporated into the candy. As the sugar-protein solution cools, it becomes move viscous and begins to trap these small air cells within its structure. The key is to keep air bubbles tiny in size and evenly dispersed throughout the product to yield a fluffy texture, and that?s where gelatin comes in.

Gelatin is termed a stabilizer because it acts to keep these air bubbles held within the sugary phase. Gelatin molecules will situate themselves right at the interface between an air cell and the continuous syrup phase forming a protective coating around each dispersed air bubble. Without a protein stabilizer of some type, these air cells would either pop, or come together to form larger and larger bubbles, which would ultimately lead to the product to collapsing on itself.

Looking at the microscope picture below, you can see the small air cells trapped within the sugary syrup matrix. The air bubbles are light, almost white in color, while the mixture of sugar and gelatin is green. The micrograph also illustrates just how much of a marshmallow is actually air, but that amount of air is needed to yield the light texture we associate with marshmallows.

Once you have a batch of marshmallow fluff made, it needs to be divided out and formed into shapes. Most marshmallows are made using extrusion, where the marshmallow mixture is pumped through pipes that ultimately leads to a knife that cuts the mixture into equal sized pieces. Other types, like Circus Peanuts, are made in starch moulds. Here the mixture is deposited into depressions of the desired shapes using large trays filled with starch. Since starch can be pressed into any shape or size, this increases flexibility during manufacturing. A chick or bunny shaped Peep marshmallow calls for much more precision. These shapes are formed by extruding the marshmallow fluff through a small, movable nozzle that can move in all directions, eventually forming complex shapes like tiny, cute animals [3].

The various textures of marshmallow products are governed by the ratio of sucrose to corn syrup in the formulation. If you use a low sucrose: corn syrup ratio you get a soft, elastic marshmallow. Most similar to Peeps or Jet Puff marshmallows. Conversely if you have a high sucrose: corn syrup ratio, the treat will have a dense, hard texture. Think more of the marshmallow bits (usually shortened to marbits) included in some of your favorite cereals like Lucky Charms. These marbits have a completely different texture than the marshmallows you would use to make s?mores.

Ultimately, these textural differences are due to the state of sucrose, that is, whether sucrose remains dissolved in the water, or crystallizes out. When using a high sucrose: corn syrup ratio, it?s more likely that the sucrose will crystallize out of the sugar syrup making the marshmallow stiff and hard like a marbit. If sucrose has crystallized, this is termed a grained marshmallow. Due to the presence of the sucrose crystals dispersed in the candy matrix, the marshmallow has a texture that tears easily, usually described as short or inelastic.

To prevent sucrose crystallization, more corn syrup can be added since it blocks sucrose molecules from coming together to form crystals. Therefore, all the sugar remains dissolved in the water and the marshmallow is ungrained. So, a low sucrose: corn syrup formulation yields a stretchy, fluffy marshmallow perfect for roasting over campfires.

Now that you know marshmallows originally were made with the sap from the mallow plant, the name marshmallow probably makes a whole lot more sense. Although mallow sap has long been replaced with protein stabilizers like gelatin, the candy would likely not exist without its early predecessors. So, cheers to the brave ones who first dug up a plant, squeezed the roots, and decided to eat that sticky sap!

[1] ?History of Marshmallows.? National Confectioners Association, 2019, www.candyusa.com/candy-types/marshmallows/.

[2] Groves, Reg. (1995). Technology and techniques in marshmallow production. Candy Industry, 160(9), 46.

[3] Hartel, Richard W, & Hartel, Anna Kate. (2008). Food Bites: The Science of the Foods We Eat. New York, NY: Springer US.