One of the oldest machine tools is a lathe machine. In 1797, an Englishman, Henry Maudslay, designed the first screw-cutting lathe which is the forerunner of the present day high speed, heavy duty production lathe.

Functions of the Lathe :

To remove metal from a piece of work to give it the required shape and size is the main function of the lathe.

This is accomplished by holding the work securely and rigidly on the machine and then turning it against cutting tool which will remove metal from work in the form of chips.

Types of Lathe :

1. Speed Lathe

- Woodworking

- Centring

- Polishing

- Spinning

2. Engine Lathe

- Belt drive

- Individual motor drive

- Gear head lathe

3. Bench Lathe

4. Toolroom Lathe

5. Capstan and Turret Lathe

6. Special purpose

- Wheel lathe

- Gap bed lathe

- T-lathe

7. Automatic Lathe

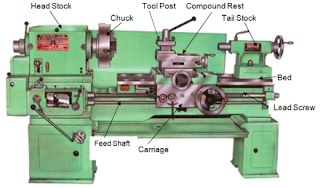

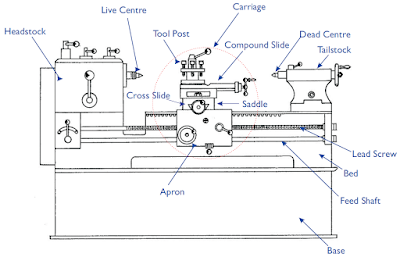

Description and function of lathe parts :

1. The Bed

The lathe bed forms the base of the machine, the headstock and tailstock are located at either end of the bed and the carriage rests over the lathe bed and slides over it.

The lathe bed is the guiding member of the lathe machine so it needs to satisfy the following condition.

- It should be sufficiently rigid to prevent deflection

- It must be massive with sufficient depth and width to absorb vibration

- It must resist the twisting

- To avoid distortion

For this point of view, the bed material should have a high compressive strength, should be wear resistant and absorb vibration.

Cast iron alloyed with nickel and chromium forms a good material suitable for lathe bed.

2. The Headstock

The headstock is secured permanently on the inner ways at the left-hand end of the lathe bed.

It comprises essentially a hollow spindle and mechanism for driving and altering the spindle speed.

3. The Tailstock

The tailstock is located on the inner ways at the right-hand end of the bed.

This has two main use:

- It supports the other end of the work

- It holds a tool for performing an operation such as drilling, reaming, tapping etc.

4. Carriage

The carriage of a lathe has various parts which serve to support, move and control the cutting tool. Parts are following below :

- Saddle

- Cross-slide

- Compound slide

- Tool post

- Apron

The saddle is an H-shaped casting that fits over the bed and slides along the ways. It carried the cross-slide and tool post.

The cross-slide consists a casting, machined on the underside for attachment to the saddle and carries location on the upper face for the tool post or compound rest.

The compound rest is mounted on the top of the cross-slide which is used for obtaining angular cuts and short taper.

The tool post located on the top of the compound rest to hold the tool and to enable it to be adjusted to a working position.

Type of tool post :

- Single screw tool post

- Four bolt tool post

- Open side tool post

- Four way tool post

The apron is fastened to the saddle and hangs over the front of the bed.

Apron contains gears, clutches, and levers for operating the carriage by hand and power feeds.

5. Feed Mechanism

Feed is the movement of the tool relative to the work.

A lathe tool may have three types of feed :

- Longitudinal

- Cross

- Angular

Lathe machine working :

The lathe is a machine tool which holds the work piece between two rigid and strong supports called centers or in a chuck or face plate which revolves.

In a tool post which is fed against the revolving work, the cutting tool is rigidly held and supported.

With the cutting tool fed either parallel or at right angles to the work axis, the normal cutting operations are performed.

The operation which is performed on a lathe either by holding the workpiece between centres or by a chuck is the following :

- Straight turning

- Shoulder turning

- Chamfering

- Thread cutting

- Facing

- Knurling

- Filling

- Taper turning

- Eccentric turning

- Polishing

- Grooving

- Spinning

- Spring winding

- Forming

The operation which is performed by holding the work by a chuck or a faceplate or an angle plate is the following :

- Drilling

- Reaming

- Borning

- Counterboring

- Taperboring

- Internal thread cutting

- Tapping

- Undercutting

- Parting-off

The operation which is performed by using special attachments is the following :

- Grinding

- Milling

Cutting Speed :

The cutting speed of lathe is cutting tool is the speed at which the metal is removed by the tool from the work piece.

In a lathe, the peripheral speed of the work past the cutting tool expressed in meters per minute.

Cutting speed = ?dn/1000 m / min

Where,

d = diameter of the work (mm)

n = R.P.M of the work

Feed :

In a lathe work, the feed of the cutting tool is the distance the tool advances for each revolution of the work.Feed is expressed in millimeters per revolution.

The depth of cut :

The depth of cut is the perpendicular distance from the machine surface to the uncut surface of the workpiece.

Depth of cut = d1-d2 / 2

Where,

d1 = Diameter of the surface before machining

d2 = Diameter of the machined surface

A depth of cut varies inversely with the cutting speed.

For the general purpose, the ration of the depth of cut to the feed varies and mostly it is 10:1.

Machining Time :

The machining time in the lathe work can be calculated for a particular operation if the speed of the job, feed length of the job is known.

Machining time = l / s * n min

Where

l = length of the job in mm

s = feed of the job in mm

n = r.p.m of the work

Lathe machine safety precautions :

While using lathe machine a safety must be needed to avoid an accident. When we work on a lathe, the following things you need to remember.

- Do not support the work piece by hand use work holding device.

- Instead of using hand use brush to clean the chip.

- No adjustment while machine is operating.

- Do not measure to attempt revolving parts.

- Make sure that all parts are secure tightly in the lathe before starting the operation.

- Never place tools on the drilling table.

- Wear safety goggals and avoid loose clothing.

- Don?t hold a chuck handle attached by the chuck and it flies at the moment of turning a lathe.

- Don?t touch the byte table into the rotating chuck and chance of damage not only a byte but the table also.

A lathe is one of the most versatile machine tools used by industries today. It is an important machine tool in manufacturing industries due to its versatility. A number of profiles can be made on a workpiece using a lathe.

Check out related articles :

Lathe machine introduction

Lathe machine function

Lathe machine parts and function

Lathe machine types

Lathe machine working

Operation on lathe machine

Types of cutting tool for lathe machine

Cutting tool signature

Lathe machine safety precautions

Cutting speed of lathe machine

Feed depth of cut and machining time of lathe machine