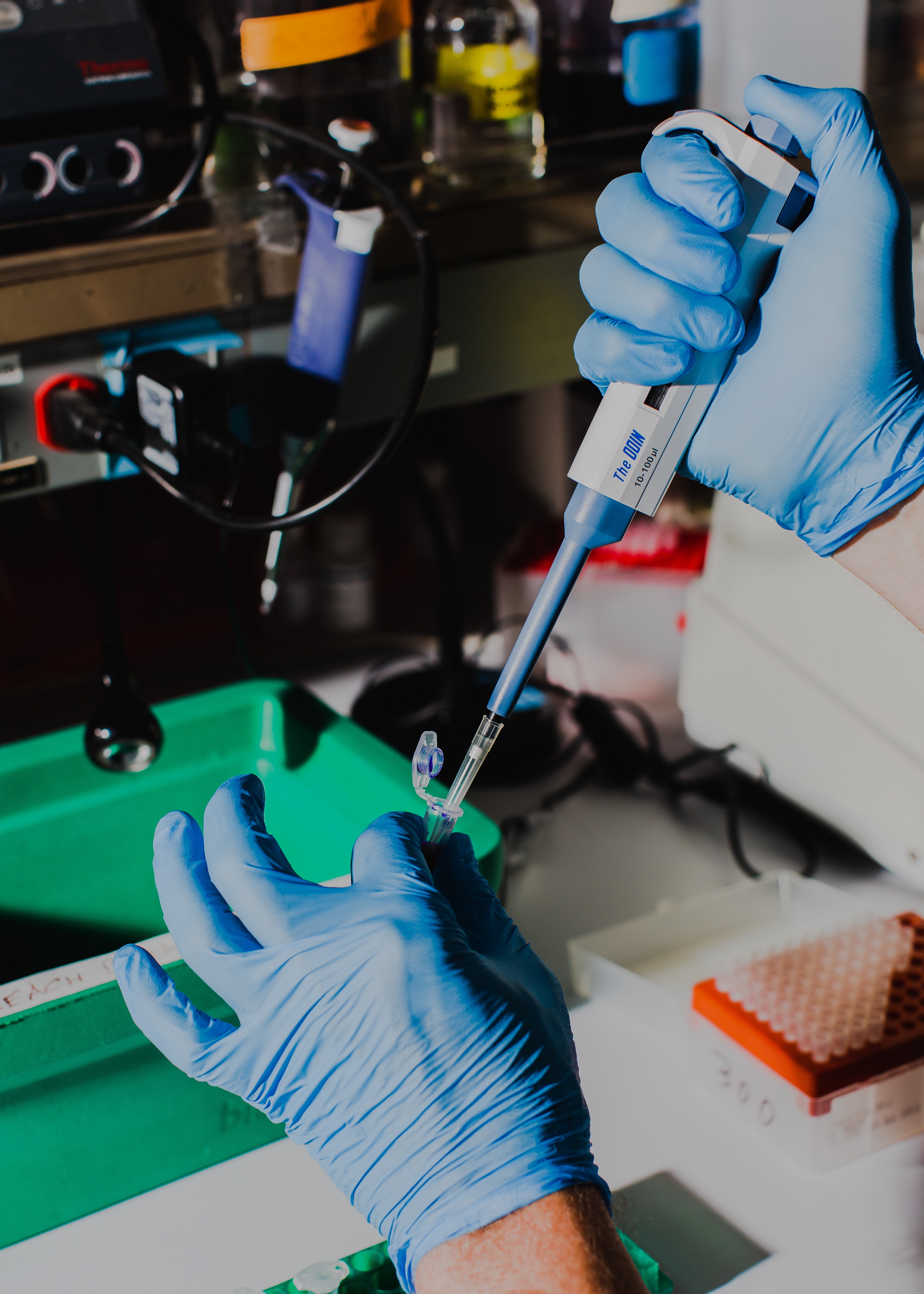

?If we can make [insulin] in our janky lab on a $10,000 a year budget, there?s no way it should cost this much,? says Thornton Thompson. Photography: Alex Welsh

?If we can make [insulin] in our janky lab on a $10,000 a year budget, there?s no way it should cost this much,? says Thornton Thompson. Photography: Alex Welsh

Diabetes is a punishingly expensive disease. In an Oakland warehouse, scientists are going DIY.

Left: Open Insulin founder Anthony DiFranco thinks a potential solution to the insulin pricing crisis is to enable patients and hospitals to create the drug themselves. Right: David Anderson, Michael Arent, and Anthony DiFranco discuss logistics at Open Insulin?s biweekly meeting.

Left: Open Insulin founder Anthony DiFranco thinks a potential solution to the insulin pricing crisis is to enable patients and hospitals to create the drug themselves. Right: David Anderson, Michael Arent, and Anthony DiFranco discuss logistics at Open Insulin?s biweekly meeting.

Open Insulin hopes to change this. The group was founded in 2015 by Anthony Di Franco, a computer scientist with Type 1 diabetes, and a longtime member of the California hacker scene. At the time, Di Franco had good health insurance through an employer, so the cost of insulin wasn?t prohibitive. But the issue became personal two years later when he enrolled in graduate school and there was a temporary gap in his coverage. He ended up paying $2,400 out of pocket for a month of supplies, significantly more than his $1,600 monthly stipend as a graduate student.

He and his collaborators think one solution to the pricing crisis lies in enabling patients and hospitals to create insulin themselves. The group works out of Counter Culture Labs in the trendy Temescal neighborhood of Oakland. The space feels like the kind of place an anarchic chemist would have set up. There are giant gourds hanging from the rafters, and jokes scrawled on the unisex bathroom door combine anti-police sentiments with jokes from The Simpsons? Sideshow Bob. At a recent meeting, one woman drank water out of a urine sample cup. (It was previously unused.) But there are also three lab benches filled with high-tech equipment, as well as beakers, pipettes, and chemicals, most of it donated or bought second-hand.

?If we can make this stuff in our janky lab on a $10,000 a year budget, there?s no way it should cost this much,? says Thornton Thompson, a molecular biologist who is part of Open Insulin. ?One of the big goals of the project is just to demonstrate that.?

David Anderson works with the yeast under a laboratory fume hood that?s surrounded by graffiti. ?You can really fuck up making medicine if you don?t do it right and people can get hurt,? says Thornton Thompson. ?That?s really important to communicate. But we know how to do it. We?ve known how to do it for a long, long time.?

David Anderson works with the yeast under a laboratory fume hood that?s surrounded by graffiti. ?You can really fuck up making medicine if you don?t do it right and people can get hurt,? says Thornton Thompson. ?That?s really important to communicate. But we know how to do it. We?ve known how to do it for a long, long time.?

?It?s not like a new drug where you don?t really know what it does,? Di Franco says. ?This is a drug that we already know what it does, and we just have to see if we made it correctly.?

In many ways, the Open Insulin group?s ambition hearkens back to the intentions of the original discoverers of the drug. In 1923, Frederick Banting, Charles Best, and James Collip sold the patent for insulin to the University of Toronto for $1 each because they believed such an essential medicine should be available to everyone who needed it.

The original patents for the insulin molecule have long since expired, but patents on parts of the production process ? a strategy that has been famously used (and arguably abused) by drug companies ? remain because pharmaceutical companies keep tweaking how they make it. Most insulins sold today are synthetic analogs that have been adjusted to last longer or act faster, which is one reason pharmaceutical companies give for why the cost of insulin has skyrocketed. These changes have prevented generic drug manufacturers from entering the market. Eli Lilly recently announced it would release its own generic version of Humalog at half the price, but without the competition offered by a dedicated generic drug manufacturer, costs aren?t likely to drop significantly any time soon.

A 10-liter culture of yeast can make insulin for 10,000 people, and the start-up costs could be as low as just $1 per person.

A 10-liter culture of yeast can make insulin for 10,000 people, and the start-up costs could be as low as just $1 per person.

?From a logistical standpoint, none of this stuff justifies the increased price,? says Thompson. ?The technology is basically the same as it has been for the last 30 to 40 years. But instead of the typical market logic of a generic [insulin] coming along to make things cheaper, we have this evergreening effect where the drug companies will make these minor modifications to the drug to extend the patent.?

Insulin costs aren?t high everywhere, though. In Spain, for example, insulin costs about $6. The pharmaceutical companies that provide insulin claim the complex U.S. insurance systems drive up the price. Specifically, they place the blame on pharmaceutical benefits managers, middlemen who serve as go-betweens for drug companies and health insurers. Representatives for the three main insulin manufacturers ? Eli Lilly, Sanofi, and Novo Nordisk ? recently testified before Congress that the list price of the drug is inflated because of the vouchers and rebates that they provide to the benefits managers, who then pass those savings on to the health insurers. As a result, they say the net price of the drug ? what the insurance companies actually pay ? is much lower than the list price.

?It?s a very distorted system,? says Dr. Mariana Socal, a scientist at the Johns Hopkins Bloomberg School of Public Health. ?The manufacturer publicizes that they?re charging, say, $500. They put the price very, very high, even though they claim that at the end of the day they?re going to be paid $200. So what is happening? Why do you need to say it costs $500 if you?re willing to be paid just $200? What?s happening to the other $300??

Socal says that the rebate money is split between the insurance providers and benefits managers, and patients see none of the savings. If you?re uninsured, you pay the list price, not the lower net price. If you are insured but have a deductible, you have to buy the drug at the list price before your insurance company will kick in. And even with full insurance coverage, the co-payment for the drug is still a percentage of the higher list price, not the cheaper net price.

?It?s a very convoluted back and forth of money that happens with very low, if any, value to the beneficiary, the insulin user,? Socal says. ?It?s absurd.?

There are currently several lawsuits accusing the three drug companies of price fixing. One class action complaint claims Eli Lilly, Sanofi, and Novo Nordisk raised the list price of insulin in lockstep over the last 20 years, stating that the companies have been ?unlawfully inflating the benchmark prices of rapid- and long-acting analog insulin drugs,? and placing them in violation of the Racketeer Influenced and Corrupt Organizations Act.

?The interests of the companies making the medicine and the interests of the patients are very different,? says Di Franco. ?The company wants to do whatever is most profitable, and it is obligated to do so in many respects. And that is rarely what is best for patients.?

Scientists make insulin by inserting a gene that codes for the insulin protein into either yeast or bacteria. These organisms become mini bio-factories and start to spit out the protein, which can then be harvested and purified.

Scientists make insulin by inserting a gene that codes for the insulin protein into either yeast or bacteria. These organisms become mini bio-factories and start to spit out the protein, which can then be harvested and purified.

?Economically, I think it?s much better to do it in this decentralized way,? Di Franco says. ?A very small investment from each patient could fulfill the patient?s needs and make insulin very close to free for everyone who needs it with this kind of technology.?

The startup costs are not insignificant. Open Insulin estimates it will take at least $10,000 to purchase the equipment, including pumps, plumbing, pH and oxygen sensors, and a sterilization system, to produce insulin on a large scale. But once the system is up and running, all you have to do is provide the yeast with sugar and growth medium, which cost next to nothing. And a 10-liter culture of yeast can make enough insulin for 10,000 people. Based on these rough calculations, Di Franco estimates that an insulin factory for 10,000 people could be created with an initial investment of just $1 per person.

Like Topol, Hirsch, the University of Washington diabetes expert, is concerned. He says that manufacturing insulin, ensuring its quality, and getting the proper dosing right can be very difficult. ?Given the fact that companies that do this for a living have trouble meeting the bar for the FDA, I find it hard to believe that someone can do this in their garage or their bathtub,? he says. ?It?s concerning that someone would inject this into their body.?

Thompson acknowledges that the recipe can be tricky to execute, but he maintains that it can be done. ?I?m not claiming that it?s so easy to make that everybody could just do it in their backyard. You can really fuck up making medicine if you don?t do it right and people can get hurt,? he says. ?That?s really important to communicate. But we know how to do it. We?ve known how to do it for a long, long time as a society.?

Jean Peccoud, the chair of synthetic biology at Colorado State University who has written about the project, is more optimistic. ?A lot of the pieces are missing, and I don?t know what the solution looks like, but it?s not unreasonable to think about developing it,? he says. ?The technology is there to make it possible to think a little bit outside of the box.?